Key takeaways:

- Even simple products have embedded electronics and software, complex products can have a lot of more including live connections to the cloud

- Electronics and software cannot be effectively added as an afterthought, products that delight their customers have hardware, electronics, software, and services integrated seamlessly

- The shift to products with embedded technology and accompanying services requires manufacturers to develop or expand competencies in areas such as model-based systems engineering, agile software development, and supply chain management

- TCS has provided embedded technology R&D and product development services for many years across a variety of industries and has competencies that can add value to customers and partners

- TCS helps customers accelerate product development using its embedded product development capabilities from chip design and software development through manufacturing and deep expertise in PLM

The growth of complexity in products in recent years has been relentless and is accelerating. Embedded electronics and software within products is a key driver of additional complexity. Using embedded technology gives manufacturers a new way to add capabilities with enormous profit potential, but it is forcing them to work differently. CIMdata has always viewed electronics and software as an integral part of the product definition, but in most companies, mechanical, electronics, and software are usually designed in a loosely coupled manner, if not in disconnected silos. Integrating all aspects of the product definition is becoming necessary to compete in most markets.

A simple example of the growing complexity is the automotive ignition key. Historically it consisted of a flat piece of metal and a big advancement was to mold plastic on one end to serve as a handle. Today’s key fob is a complex electro-mechanical device responsible for authentication and security via secure wireless signals. Manufacturers are now able to produce identical key fob assemblies and program each of them to work only with a single vehicle. In the old days unique physical keys needed to be manufactured for each car.

A much more complex example is the autonomous or self-driving car. Automation needs to take over many functions that previously were done by humans. The advancement to making autonomous decisions in real-time based on the unpredictable environment external to the car is huge. And it has to be perfect or the autonomous vehicles will not be accepted.

Modern cars are partitioned into many sub-systems: engine control, braking, steering, entertainment, communication, safety, and more. Autonomous operation requires a system to manage all these subsystems while accepting input from navigation systems, the external environment (traffic, pedestrians, emergency vehicles), and regulatory input (speed limits, stop signs, traffic lights, etc.). The autonomous decisions are implemented in software within embedded computers in the vehicles. These must correctly control physical systems to ensure safety and minimize liability.

The proliferation of smart, connected products is happening quickly across most industries, not just automotive. Embedded technology is being incorporated in consumer and industrial products making for an exciting time to be alive. But, it also is stressful for those responsible for developing products on time, on budget, with the quality and features customers expect.

Embedded Development

Historically, embedded technology was created with purpose built computer technology and one-off software and then grafted onto mechanical components. Since this technology was expensive, it was primarily used in high-value products such as cars and airplanes. As computer developers drive down the cost of computing in line with Moore’s law, embedded technology including off the shelf processors and sensors are being incorporated into more and more products. Today only the most basic products don’t have electronics and software, and as the Internet of Things grows, more and more low priced products will become smart and connected.

Using electronics, software, and the cloud to add features to products can reduce cost and make products easier to differentiate when compared to using purely mechanical or physical solutions. Replacing a radio knob that controls volume with a slider on a screen reduces manufacturing cost by eliminating several physical components. Electronics are usually more reliable than mechanical solutions reducing warranty and maintenance costs, however different skill sets are required to develop and manage the additional complexity.

While software features have low manufacturing cost, and can enable capabilities that are impossible to create in the mechanical world alone, there are downsides. Coordinating the development of electronics, software, mechanical, and cloud technology can be extremely complicated. Few organizations have all the skills needed, so portions of product development and production are commonly outsourced to a supply chain. Incorporating embedded technology can add additional regulatory requirements, again added to complexity.

The automotive domain landscape is comprised of areas which include conventional as well as hybrid and electric powertrains, body and chassis electronics, safety, infotainment, advanced driver assistance systems (ADAS), and diagnostics. Each domain interacts within and across other domains.

Embedded technology uses a wide variety of tools and processes ranging from chip and circuit board design, wiring and cabling design, software development, and system modeling to simulate the interaction and integration of communications, controls, sensors, and actuators. CIMdata has seen an explosion of interest in the systems engineering discipline to manage the complexity of smart connected products. In addition to design, systems engineering can model and manage the complete development cycle from requirements through design, testing, validation, and production, helping ensure that products will meet requirements and be successful.

For companies just starting down the embedded technology path or experienced companies looking to improve their processes CIMdata recommends consideration of several key elements. First take a holistic view of your product using a modern systems engineering viewpoint. Choose supporting technology carefully and ensure the implementation is sustainable and flexible. Finally, don’t feel that you have to do it all, partnering is common in the electronics and other industries so partners and subcontractors are available to get necessary competencies.

TCS’s Embedded Offerings

Tata Consultancy Services (TCS) is one of the largest global enterprises focused on providing IT services, consulting, and business solutions. Their over 340,000 employees support virtually all industries. They have over 5,000 specialists supporting embedded technology within a variety of industry verticals including automotive, aerospace and defense, and industrial and high-tech, and have competency centers that do a range of embedded related R&D and provide services from chip design and product engineering through production.

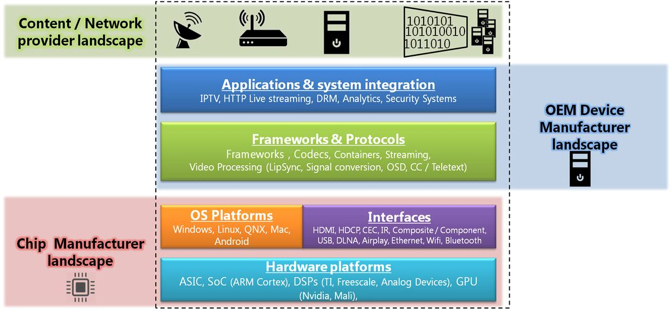

Figure 1—TCS Provides Services from Chip Design To Hardware and Software Development and Cloud Support across a Wide Range of Industrial Domains

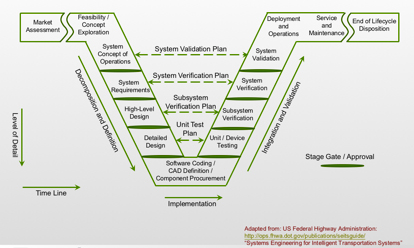

Figure 1 shows the range of services TCS can provide to their clients. They have experience from concept through production to help OEMs and component manufacturers succeed in the market. Their offerings span the value chain represented in the systems engineering Vee cycle, a common way to represent processes used in complex product development as shown in Figure 2. In addition to hardware prototype design and low volume manufacturing, TCS also develops and supports cloud-based connected solutions that can transform business models. At CIMdata, we see many industrial clients leveraging cloud services to generate new high margin revenue streams.

TCS has both service provider and actual practitioner experience to draw from to solve customer problems. Their engineering teams partner across the entire systems engineering Vee cycle or at a specific phase as required. In addition, they provide support to the top global manufacturers in a variety of areas including IT and systems integration support, as well as PLM solutions. They have developed intellectual property across domains such as defense targeting, wireless charging, automotive safety algorithms, powertrain electronic throttle controls, infotainment, and ADAS systems. CIMdata is looking forward to reviewing more case studies on TCS’ successes.

TCS Embedded Solutions support most aspects of in-vehicle electronics development, including product development, hardware design, development and prototyping, verification and validation, qualification and certification, model-based development, AUTOSAR implementation, and functional safety lifecycle management. Their software expertise ranges from firmware through operating systems, middleware, applications, and cloud services, the full embedded technology stack.

Figure 2—The Systems Engineering Vee Cycle Representing the Multi-Discipline Product Lifecycle of Complex Products

TCS in collaboration with its R&D practice has also developed a Software Product, TCS ECA (Embedded Code Analyzer) for static analysis of embedded software. This analyzer uses a variety of techniques to detect critical and hard to find defects to offer better product quality while balancing precision, scalability, and performance.

TCS has set up a manufacturing facility in Goa, India for prototype development and for low volume manufacturing. TCS is proud of their state of the art equipment, soft tools, and manufacturing processes organized to support the product development lifecycle. They recently developed a new vehicle diagnostic device, of which 20,000 devices have been delivered. For this product TCS also carried out environmental and compliance testing and certification for 76 countries. TCS also has a strong partnering record with more than 70 patents co-authored with customers. They have long-term relationships with customers, especially within the automotive industry, in some cases up to 15 years. CIMdata sees TCS as a good partner, one that is committed to the success of their customers, but it will be interesting to see how their relationships with partners evolve if TCS continues to develop and deliver products.

Summary

Consumer and industrial products are evolving at a rapid pace by incorporating embedded technology. These new products have features that people didn’t even know they needed, and now are nearly indispensable, like GPS and real-time traffic navigation. But, the pressure of new product requirements and increased product complexity placed on product producers is enormous. If they don’t adapt to these new challenges of product development, they run the risk of going out of business.

To address the new challenges, leveraging suppliers and developing partnerships is a sound strategy. TCS has a long history of helping customers with embedded hardware and software product development. Based on CIMdata’s PLM and Industrial consulting experience, we believe TCS has the skills and experience to help companies bring products with embedded electronics and software to market. If you need help in developing such a smart, connected product quickly or if you need to transform your PLM landscape to align it to the changing nature of product development, you may want to consider TCS.