Using low-code tools delivers competitive business advantage

Key takeaways:

- Growing economic and social uncertainties, and continually changing market issues (competition, product complexity, customer demands, and regulatory requirements) are affecting all industrial companies and their value chains.

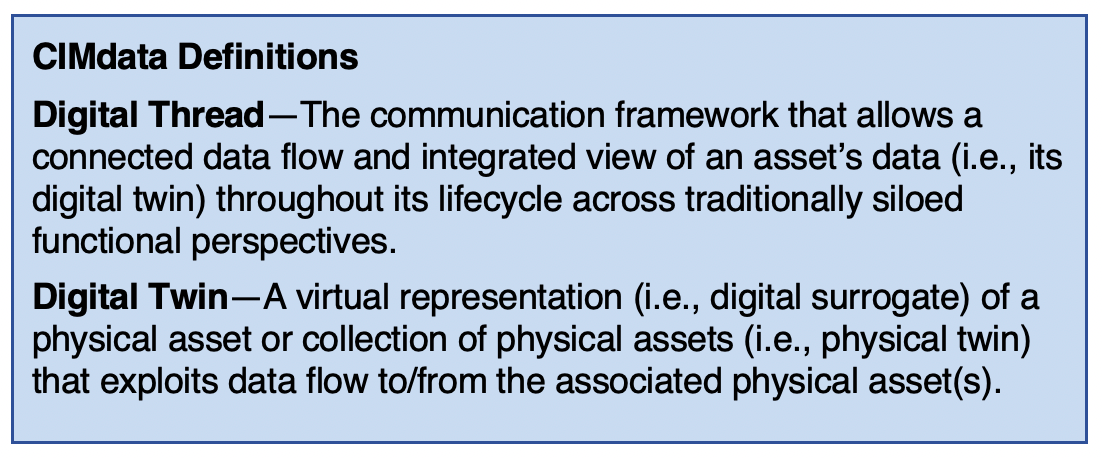

- To successfully manage complexity and risk, modern value chains require technology characterized by hyper-connectivity (on-premises, cloud, and edge), and are personalized for ease of use and fit-for-purpose. These key criteria best support end-to-end workflows and a comprehensive digital twin strategy that enables an Industry 4.0 vision.

- Siemens’ Xcelerator portfolio enables end-to-end digital threads across value chains and industrial vertical markets. The open backbone supports design, engineering, production operations, and service phases of the complete lifecycle by integrating best-of-breed solutions and applications from Siemens and other solution providers.

- Siemens’ Mendix low-code development platform connects and extends Xcelerator solutions and applications, via composing rather than coding, thus enabling integrated, personalized solutions required to improve business performance.

Value Chain Issues Challenging Manufacturers

Products continue to become more complex, more capable, more connected, and part of “systems of systems” networks. Increased complexity of cyber-physical products with an ever-increasing amount of embedded software, electronics, sensors, and new IoT-enabled operating environments demands thinking beyond traditional product development, manufacturing, service, and supply chain paradigms. Industrial stalwarts and start-ups alike must leverage new technologies to digitalize development, production, operation, and service lifecycles to create new value chains and revenue streams, all while maximizing and modernizing existing investments.[1]

Maintaining and evolving a successful value chain requires manufacturers be able to quickly reconfigure it to address changing requirements. New partners and suppliers will need to participate as product and market requirements evolve. Each will have different functional tools and systems that must be integrated easily and quickly into the overall value chain.

Historically, IT systems already in place were not easy to extend internally, let alone across value chains. Businesses had to allocate significant resources just to sustain these systems and could not create the new systems and integrations required to meet rapidly changing business challenges. Yesterday’s R&D tools and IT solutions no longer meet the performance, connectivity, and user experience expectations of today’s social media-oriented, digital first workers. However, new development technologies, e.g., low-code tools, microservices, combined with proper governance are now making it easier to compose applications that incorporate new and existing data, systems, and processes to meet expectations and enable accurate, rapid decision-making processes.

Characteristics of a Modern Value Chain

A value chain is a set of activities that a manufacturer performs to transform a product or service from idea to reality, ultimately delivering value to the end customer. It connects many diverse, distributed entities, internal and external, seamlessly via bi-directional digital threads. It spans the extended enterprise–involving partners and customers to form an integrated, heterogenous ecosystem for collaborative creation, production, and service. Effective value chains must encompass heterogenous technologies, processes, systems, and data sources.

A value chain is a set of activities that a manufacturer performs to transform a product or service from idea to reality, ultimately delivering value to the end customer. It connects many diverse, distributed entities, internal and external, seamlessly via bi-directional digital threads. It spans the extended enterprise–involving partners and customers to form an integrated, heterogenous ecosystem for collaborative creation, production, and service. Effective value chains must encompass heterogenous technologies, processes, systems, and data sources.

Efficient value chains must be deliverable on multiple IT infrastructures in a mix of on-premises, cloud, and edge, so that companies can flexibly adapt to the way their business should optimally operate amid evolving market and business conditions. For maximum flexibility, these value chains should incorporate personalized, easy-to-use, composable applications that solve complex business problems and deliver end-customer value.

Siemens Xcelerator as a Service Portfolio

Siemens Xcelerator is an integrated portfolio of software, services, and domain expertise, along with application development, integration, and IoT connectivity solutions designed to enable industrial digital transformation. Xcelerator is both a wide and deep portfolio encompassing technology and solutions that support the full design, realization, and optimization of the extended value chain lifecycle.

- Design—All domains and functions such as mechanical, electrical, electronic, software, formulated/process

- Realization—Manufacturing process planning, simulation, production operations, and automation commissioning

- Optimization—Track, analyze, and optimize in-service use and performance and schedule maintenance

Delivered both on-premises and as-a-service, the Xcelerator portfolio is built on a modern cloud architecture, creating the basis for the extended enterprise value chain that supports digital threads and makes comprehensive digital twins actionable across domains and disciplines.

Mendix and MindSphere are key as-a-service components of the Xcelerator portfolio that connect smart devices and systems, automate processes, and bring multi-experience personalization per user requirements. These are fundamental capabilities required to create and evolve efficient, resilient value chains.

Siemens Mendix Low-Code Application Development Platform

Mendix is a modern, application development and data integration platform with an extensive developer ecosystem. An integral part of the Siemens Xcelerator portfolio for industrial transformation is that it is used to develop business-specific, personalized solutions and enable fast adoption.

Mendix enables citizen developers, business analysts, and power users to rapidly compose and deploy for-purpose, personalized, multi-experience applications across their value chains. Companies can leverage and extend both Siemens and non-Siemens’ solutions to develop business-unique applications and connect to data sources regardless of location and format. As a result, these tailored applications enable users to make fast, accurate decisions within and across product development, manufacturing, operations, and service.

Mendix is often used to:

- Create flexible, composable, applications and solutions to support business processes

- Reduce complexity and maintenance of internal and external system, application, and data integrations

- Extend digital transformation across multiple domains within an enterprise

- Extend the power of core systems without re-coding them

- Create engaging user experiences and speed adoption

For more detailed information on Mendix, check out the eBook titled “Low-Code Platforms Accelerate Business Value” published in November 2021. It can be accessed from the CIMdata website[2] and from Siemens. Additional commentaries on Mendix (e.g., “Mendix and MindSphere: Integrating IT and OT to Deliver Business Performance”, and “Connecting the Past to Tomorrow with Mendix”) are also available on the two websites.

Mendix and MindSphere: Working Together to Enable the Flexible Value Chain

MindSphere is Siemens’ industrial IoT as-a-service solution that collects, analyzes, and acts on data from connected products and systems, smart devices, and the factory floor. Because MindSphere is Mendix-enabled, developers can use Mendix to compose rich, personalized IoT applications that link data and processes from MindSphere with the rest of the Xcelerator portfolio and beyond to form the basis of a complete value chain.

The data analysis capabilities of Mendix and MindSphere enable developers to derive rich insights from the data captured within MindSphere. Used together, they provide essential functionality to create an efficient, resilient, flexible value chain.

Examples of key value chain functionality enabled via Mendix and MindSphere include:

- Real-time asset performance and predictivity

- Quality sensing

- Remote monitoring

- Tailored workforce training and augmented operations

- Hazard alerts, detection, and actions

The Smart Biosphere: A Case Study

The Biosphere Foundation is the non-profit trading arm of the North Devon UNESCO Biosphere reserve (NDUB), one of 735 global biospheres covering 5 percent of the earth’s surface. It leverages technology to create scalable and credible market infrastructure that connects institutional level investments with nature-based interventions to address climate change, restore nature, and create community prosperity. The mission of Biosphere states: “Promoting innovative approaches to economic development that are socially and culturally appropriate and environmentally sustainable.”

The Biosphere Foundation developed the “Smart Biosphere” concept in 2019. The team then launched this initiative in April 2022 using MindSphere and Mendix. They can now collect IoT data through a growing sensor network with various data types—such as weather data. With so much data collected, the MindSphere IoT for Makers solution (which combines MindSphere and Mendix) provides strong analysis, as well as the ability to integrate skills through widgets, and support customer facing applications. The developers have a single interface to work with and the operating team has the strength of MindSphere to fall back on for security, data acquisition, and operational reporting.

“With MindSphere and Mendix, we built an environmental intelligent digital twin application. It creates an integrated decision support tool for water management, covering water quality, flood risks, agricultural management and run off, and the placement of natural capital interventions,” said Mr. Rob Passmore, Commercial Lead of the Biosphere Foundation.

Summary

The many challenges manufacturers face today are forcing them to rethink how they operate. Value chains, the set of activities that a manufacturer performs with its partners to transform a product or service from idea to reality and deliver value to the end customer need to be built or rebuilt to deliver all their potential value.

Technology has progressed significantly in the last few years to enable the easy integration of data and processes across the extended enterprise. But to be successful, more than integration is needed. Users need personalized, easy-to-use apps that help them optimally perform their tasks and meet business and customer expectations. Companies need modern technology-based solutions that can support the entire extended enterprise, while meeting continually evolving business and end user requirements. Low-code development and integration tools are transforming how businesses connect data and processes across their platforms while continuing to meet growing and everchanging end user challenges.

Siemens Xcelerator portfolio has the architecture, open technology, and comprehensive, integrated solutions to support the complete concept to end-of-life value chain, create end-to-end digital threads, and enable industrial digital transformation. Mendix provides the tools and technology companies require to meet the challenges of creating solutions and composable applications users need to perform their tasks.

CIMdata continues to be impressed with Mendix and the results it can bring to companies. Manufacturers and commercial businesses should consider using Mendix to support their digital transformation, IT modernization, and low-code development and integration needs as they create and participate in value chains that are critical to their business success.