Key takeaways:

- As a strategic part of Siemens AG, Siemens PLM Software is delivering a comprehensive and cohesive end-to-end solution.

- With more than US$10B in acquisitions, Siemens PLM Software (Siemens) has expanded significantly and continues to deliver solutions to support the digital transformation of industry, including expanding to operations and service.

- Both of Siemens’ design solutions, NX and Solid Edge, offer improved workflow for generative design techniques including topology optimization by leveraging Convergent Modeling that includes faceted and precise geometry, additive manufacturing, and reverse engineering.

- Siemens’ actionable, holistic digital twin composed of multiple functional twins, includes product, performance, and production, and is broader than other digital twin solutions in the market.

- The acquisition of Mentor is bearing fruit on many fronts, including wire harness design and electronics manufacturing. Siemens can now offer a multi-domain IT environment that supports the development and ongoing operation of today’s smart, sensor-rich, connected products, as well as supporting tomorrow’s products, like autonomous vehicles.

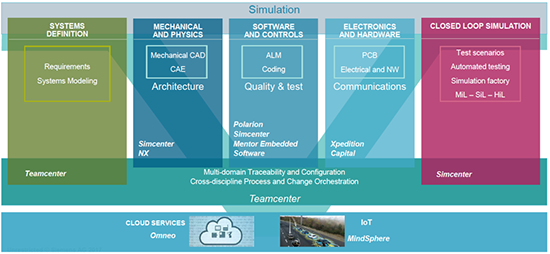

CIMdata recently attended Siemens PLM Software’s 11th annual analyst conference in Boston, Massachusetts September 5th through 8th. This event continues to expand as Siemens’ solution portfolio grows, with almost 100 industry analysts and journalists in attendance.[1] The theme of this year’s event was “Realizing the Digital Twin.” Siemens described their approach to creating a holistic, actionable set of digital twins that encompass all aspects of the product lifecycle, spanning product, production, and performance. Their holistic digital twin strategy supports their approach to systems-driven product development shown in Figure 1. Since the 2-1/2-day event was so rich in content, this commentary will provide highlights spanning the main elements shown in the figure.

In the opening keynote, Dr. Jan Mrosik, CEO, Siemens AG Digital Factory Division, stressed the essential requirements for companies throughout the manufacturing industry—improving both speed to market and flexibility. According to Dr. Mrosik, all Siemens AG divisions are driving digitalization technologies and the Digital Factory group has a goal to help the global manufacturing industry go digital as companies move toward Industrie 4.0. Siemens AG has stated that going digital is not sufficient—companies need to embrace digitalization that uses digital strategies and associated enabling technologies to help change business models, a sentiment with which CIMdata strongly agrees. To power this vision, Siemens is building digital twins of the entire value chain process—providing digital twins for all aspects including mechanical, software, electronics, simulation, production, service, etc. CIMdata agrees that Siemens’ concept of the holistic digital twin has great potential to improve lifecycle processes and be a competitive differentiator when it is fully implemented.

Figure 1–Systems-Driven Product Development

(Courtesy of Siemens PLM Software)

To reach their broad vision, Siemens AG has spent over US$10 billion on strategic acquisitions to expand their PLM portfolio. The biggest single investment was Mentor Graphics, at about $4.5 billion. Mentor Graphics (now called Mentor) has long been a leader in the electronic design automation (EDA) space, as reported by CIMdata’s global PLM market analysis. Mentor also brings strengths in computational fluid dynamics (CFD) and digital manufacturing that are very complementary with the existing Siemens portfolio. Siemens is working to rapidly integrate Mentor’s capabilities in their authoring tool workflows. In addition, Dr. Walden (Wally) C. Rhines, Mentor’s President and CEO, emphasized that unlike their EDA competitors, Mentor gets over 50% of their revenues from systems work, not just tools. This strength fits perfectly with the systems view of Siemens, and brings additional tools to extend that view to include electronics in their workflows and digital twins. CIMdata is impressed that the integration initiatives between Siemens and Mentor, which started over a year ago, have smoothly transitioned and accelerated since the acquisition, resulting in demonstrable examples of a cross-domain, mechanical-electrical production digital twin. (During the sessions, they made it clear that the collaboration intensity had increased between the then partners before the acquisition was finalized, making it easier to move quickly once it was executed.) Based on CIMdata’s market research, the Siemens/Mentor combination should be the largest PLM solution provider for calendar year 2017.

As shown in CIMdata’s global PLM market research, Siemens is a leader in automotive, a strength they continue to reinforce. Autonomous vehicles are causing a shift from testing to simulation to perform validation. Mr. Tony Hemmelgarn, Siemens’ CEO and President, noted in his keynote that massive validation and verification (V&V) cycles are needed to support all the possible situations an autonomous vehicle will face. Conducting physical validation for billions of hours is not feasible making simulation even more important. While CIMdata does not believe that simulation will eliminate physical testing, it does allow much broader test coverage and, when combined with hardware-in-the-loop (HIL) and software-in-the loop (SIL), it can support a much more comprehensive and rapid validation and verification process.

During the event, Siemens noted their recent acquisition of TASS International, a global leader in automated driving solutions. This acquisition adds strength to their capabilities in simulation and test services in the automotive space. TASS’ customer list includes most of the automotive OEMs globally, as well as many Tier 1 and Tier 2 suppliers. While automotive is TASS’ focus, they also have quite a number of leading aerospace customers, again a nice synergy with Siemens’ global business in aerospace and defense. CIMdata believes the TASS acquisition is another great pick that will help expand their Simcenter vision and associated capabilities. CIMdata anticipates that it will also help Siemens improve their customers’ V&V process, both for autonomous vehicles and other complex system products.

In today’s smart, connected world, companies must adapt to ensure their survival. Some talk of data as the new oil, lubricating and powering business success. In his remarks entitled “Digitalization Changes Everything, Everywhere,” Mr. Hemmelgarn emphasized that just gathering data to identify a problem is not enough. Unfortunately, this is where the value propositions of many solution providers end. You need to also identify how to fix the problem. Siemens plans to use their holistic digital twin approach and associated enabling technologies, which can accurately predict reality and operational outcomes, to let manufacturers drive the right fix. One way they will achieve this diagnostic goal is through their MindSphere platform which provides information that can drive real product and production design changes, not just service adjustments. Many solution providers understand this need, but most are still working out the details of just how and where this information will feedback into the product lifecycle processes.

According to Siemens, MindSphere provides the foundation for systems-driven product development as shown in the figure. Mr. Stephen Bashada, Executive Vice President and General Manager, Cloud and Data Services, presented MindSphere and its related products and services. MindSphere is positioned as a “cloud-based, open IoT operating system,” delivered as an open platform as a service (PaaS) offering. MindApps are supporting applications that run on their MindSphere infrastructure. Products, machines, assets, and edge devices can be easily connected to the MindSphere platform using MindConnect embedded software or as dedicated, integrated devices. Mr. Bashada mentioned that Siemens has a growing suite of MindApps and an open partner ecosystem providing applications and services. They demonstrated how they close the production digital twin loop with MindSphere and analytics for continuous quality improvement across the entire product lifecycle. They are investing heavily in MindSphere and Mr. Bashada presented a few business cases showing MindSphere in operation demonstrating the value of this approach. Siemens AG is well positioned as a software provider and a manufacturer and user of IoT devices. CIMdata believes this combination will help Siemens fully deliver on its holistic digital twin strategy. Rittal, a Siemens customer, described how they are improving the uptime and designs of their machines by leveraging information from MindSphere.

The way products are designed will also have to change in a smart, connected world to meet new design and manufacturing requirements. Mr. Bob Haubrock, Senior Vice President, Product Engineering Solutions, highlighted “Next Generation Design with NX.” In keeping with the broad Siemens strategy positioning of “Ideation, Realization, and Utilization,” Mr. Haubrock spoke of their advances in ideation supported by generative design processes. By leveraging their Parasolid geometric kernel’s addition of faceted geometry, their “Convergent Modeling” approach has been extended to provide a smooth, integrated workflow from design to manufacturing, including additive manufacturing processes, by enabling faceted data from scanning or topology optimization processes to be mixed with classic B-rep data. A second strong theme Mr. Haubrock outlined for on-going NX improvements was integration with the newly acquired Mentor electrical design capabilities to support cross discipline printed circuit board (PCB) integration and wire harness design. One of the most interesting advances Siemens presented was the integration of Capital (a context-aware electrical design and layout solution that is part of the Mentor suite) with Teamcenter and NX. The Active Workspace user interface (UI) for Teamcenter is already integrated within Capital. This integration will help smooth the design of discrete products that include electronic subsystems. These design advances also extend to their Solid Edge portfolio.

Mr. Dan Staples, Vice President Product Development, presented enhancements to Solid Edge available in its newest release, Solid Edge ST10. Paralleling generative design in NX, Solid Edge ST10 also takes advantage of Convergent Modeling to offer users topology optimization based on specified parameters, such as a specific component material, a design space (or envelope), and permissible loads and constraints. Partnering with Bentley Systems to leverage their scanning technology, Solid Edge ST10 offers improved reverse engineering capabilities, again leveraging Convergent Modeling. CIMdata sees these enhancements as a step forward to provide users with an improved workflow in generative design and reverse engineering tasks. One major application for generative design is to support another important trend, the production use of additive manufacturing (AM). Siemens has been diligently working in this area for some time, leveraging AM work being performed by Siemens Corporate Technology group. During his remarks, Mr. Hemmelgarn announced a relationship with HP, linking Siemens NX Additive Manufacturing capabilities with HP’s Multi-Jet Fusion printers. In a later session, Mr. Aaron Frankel, Senior Director of Marketing at Siemens, provided more details on their end-to-end AM strategy, including barriers to industrializing AM for production of end-use parts. He also introduced the “Part Manufacturing Platform” that enables an ecosystem of members to design, analyze, validate, source, and print parts globally. The platform provides a flexible infrastructure for on-demand design and manufacturing targeted for maintenance and low volume production situations. Mr. Frankel concluded his presentation by introducing the NX AM software module and highlighted how NX supports Design for Additive Manufacturing (DfAM) with end-to-end simulation, including automatic parts nesting in the build tray. Mr. Frankel then announced the “NX AM for HP Multi Jet Fusion” product, which specifically leverages HP’s Multi Jet Fusion technology. The certification agreement that Siemens PLM Software and HP signed will provide users more confidence in the NX/HP combination, and should help drive HP Multi Jet Fusion (MJF) Technology adoption in the market.

Ms. Michelle Bockman, Global Head of 3D Printing at HP Inc., gave an overview of HP’s MJF Technology. Ms. Bockman recently joined HP from GE Digital, where her experience as Executive Vice President should help her lead and expand HP’s AM Printing business. Ms. Bockman closed with an example of partnering with Siemens by showing design and production of a simple mechanical part with an Industrial Internet of things (IIoT) device imbedded in it during printing. The example highlighted how AM enables IIoT and provides real business intelligence information (i.e., number of cycles, wear, etc.) that will enable preemptive maintenance of production equipment. The presentation emphasized how the strategic relationship between Siemens and HP will industrialize AM for production of end-use parts.

Finally, Siemens is making rapid progress on integrating Mentor’s strength supporting electronics manufacturing into the Tecnomatix portfolio. Mr. Zvi Feuer, SVP Manufacturing Engineering Software, Mr. Rene Wolf SVP Manufacturing Operations Management Software, and Mr. Dan Hoz GM of Mentor’s Valor division presented how Siemens can now combine traditional mechanical manufacturing workflows and electronic workflows. For example, Valor adds PCB to existing strengths on the shop floor in Tecnomatix. Flomerics adds the ability to apply CFD to simulate both product manufacture and their operations. This is yet another example of how Siemens is expanding their vision and ability to execute across the holistic digital twin. As at all the analyst events, Siemens had several customers talking about their own digital journey, the issues they are facing, and how they are using Siemens’ solutions to address them. For example, Mr. Alan Wardle, Enterprise Architect—Civil Aerospace, at Rolls-Royce, described their closed loop manufacturing journey. He stated that they wanted a PLM-centric execution system, not an ERP-centric one for their 21 MES-enabled plants. According to Mr. Wardle, quality and safety were the drivers, first defined in engineering and then transitioned to the shop floor. Mr. Wardle commented that Rolls-Royce uses the digital twin for optimization and variation, something they long needed. Their overall solution includes Teamcenter (for PLM) and SIMATIC IT (for MOM). He stated that the key lesson learned was to put people first, then pick and implement the needed technology, long a tenet of CIMdata’s industrial consulting.

Summary

CIMdata is impressed with the broad and deep portfolio of solutions assembled by Siemens. They have developed and/or acquired technology and solutions that provide value across the entire lifecycle and can be used to connect the silos of mechanical, software, and electrical and electronics. Their offerings span from ideation to requirements management to systems engineering supporting PCB, semiconductor, wire harness, software, mechanical, and electrical systems across ideation, design, develop, simulation, test, validation, manufacture, and service as shown in the figure. They are using their definition of an actionable, holistic digital twin to create closed loop environments that enable enterprises to not just monitor a product but to take informed corrective actions to improve design, development, production, and service. CIMdata agrees that only such platform thinking allows a proper model-based design concept approach, where simulation plays a central role and enables system-driven product development. Their comprehensive and structured platform approach includes foundational elements such as cloud service layers (Omneo and MindSphere) and a collaboration backbone (Teamcenter) over domain-specific processes supporting domain- and physics-specific execution. No company, even one as large as Siemens, can do all this work alone. To support both innovation and technology adoption, Siemens AG established “Next 47,” described by Mr. Mrosik as an incubator for startups to help expand their ecosystem of providers and partners. CIMdata thinks this is a very interesting idea that should result in new and expanded uses for Siemens’ technologies and solutions.

While Siemens has made significant progress, there is a lot of work still to do. CIMdata looks forward to seeing how and when Siemens leverages the full scope of their suite.