Key Takeaways

- Successful adoption of ADAS and AV requires trust—trust by the end users, and trust in the tools and solutions used to design, develop, and validate the vehicles.

- Frontloaded engineering is required to establish and maintain the needed trust.

- Modern virtual engineering ecosystems keep regulations and safety standards visible helping ensure compliance throughout the complete lifecycle, from ideation throughout product architectural studies and product planning.

- Siemens Digital Industries Software solutions enable collaborating, improving design decision-making earlier—from the beginning of ideation (aka, frontloaded engineering) through enhancing product and feature upgrades.

Introduction

How can automakers deliver trustworthy and compliant ADAS and AV systems that function effectively in the widest possible range of conditions? Historic vehicle development methods and processes are too slow, relying on physical prototypes for integration and performance verification and validation. Virtual feature exploration driven by trusted models will accelerate systems engineering while reducing the time and cost to verify and validate physical systems.[1]

Moving engineering decisions earlier in product development by using virtual engineering for prototype mockups and performance assessments is the key characteristic of frontloading, allowing for faster development as engineering processes are reorganized. Frontloaded vehicle and systems design is needed to maximize ADAS features. It is a key to establishing trust in the overall vehicle design and performance. The definition, development, and refinement of ADAS and AV features must become continuous starting at vehicle concept initiation. This is an emerging competitive frontier for all ADAS/AV competitors, whether they are startups or experienced OEMs. In an earlier CIMdata whitepaper[2] three Siemens ADAS narratives were introduced, including this one defining the application of frontloaded engineering to improve virtual development of ADAS and AV features.

Frontloading Accelerates Ideation in Systems Engineering

There are competitive benefits of having techniques and processes that allow exploration of alternative candidate features to be virtually implemented thus enabling performance and behavioral assessments without expensive and slow to develop and costly physical prototypes. Virtual engineering’s promise is that systems algorithmic development has fewer and fewer prototype learning cycles as virtual builds and performance assessments become more trusted. This accelerates product development and improves safety compliance. Trust comes from experience correlated to the models of the system. Models can automatically adjust to reflect field measurements and thus more accurate models form the foundation of an environment where new ideas can be assessed quickly. Balancing priorities as new ideas are refined into realistic features is needed as early as possible to both optimize the design and establish trust in that design.

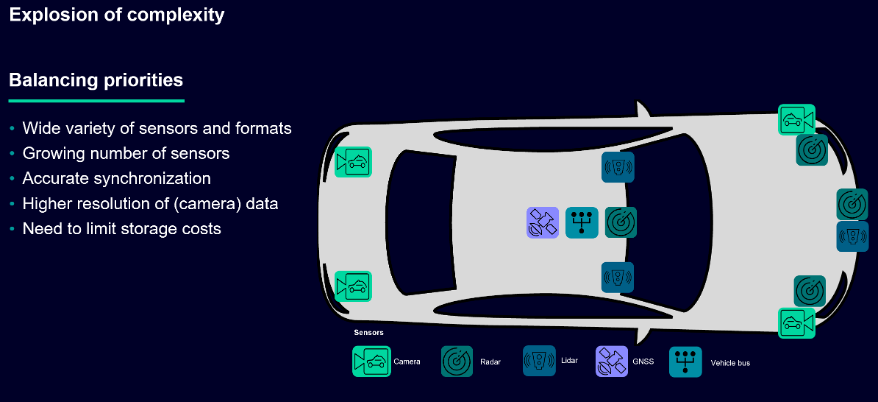

Figure 1—Sensor Proliferation improves Safety, but Complexities Must Be Managed From the Start

(Courtesy of Siemens)

The increasing vehicle complexity driven by more software and data sensors requires performance investigations on many architecture variants to identify which ones will meet all—sometimes conflicting—performance requirements. To determine which ADAS and autonomous driving features add the most value, systems engineers need to understand earlier in the development cycle if they can be incorporated successfully into the existing electrical and electronic (E/E) architecture and its constraints. Frontloading design decisions about the hardware, software, functionality reuse, and critical operational scenarios eliminates later stage prototype costs. A functional digital twin enables the capability to virtually iterate designs and scenarios across systems engineering’s ideation activities, feature definition, exploration, implementation, and optimization. Having all related data, targets, and compliance requirements associated with the trustworthy, digital twin models, ensures that systems are developed for electronics and electrical systems that meet the needs of the driver and the intent of the features while balancing power consumption to support the high-performance computing required for ADAS and AV systems.

Fast-paced design of features are key to success for many different ADAS and AV products. The electrical, embedded software, and mechanical aspects of such designs improve when they are designed virtually and validated and compared earlier in product development—the essence of frontloading engineering.

The Important Role of Reliable Digital Twins

Effective feature development proceeds virtually when a reliable digital twin exists. The system models’ reliability improves as experiential data trains the digital twin. By using the latest “mature” digital twin, new features can be assessed and compared up front before any hardware is built.

Effective feature development proceeds virtually when a reliable digital twin exists. The system models’ reliability improves as experiential data trains the digital twin. By using the latest “mature” digital twin, new features can be assessed and compared up front before any hardware is built.

Such a digital twin, connected via digital threads, enables a trusted and virtual systems engineering environment allowing engineers to generate, simulate, analyze, and predict production performance before investing in physical prototype parts. The thread connects data leveraging product lifecycle management (PLM) and empirical data from real customers, including 3D design, performance simulation, and usage scenarios.

Using digital twins of the product enables accurate simulation and prediction of the physical twin’s behavior (and that behavior can be used to update and verify the virtual models and processes). Data captured from the physical twin can be replayed within the digital twin to expose and predict opportunities and to develop solutions that are then evaluated on the digital twin.

Siemens’ ADAS and AV Solutions Enable Frontloaded Engineering

By identifying and implementing frontloaded engineering capabilities, Siemens has assembled solutions that support automakers’ ability to bring new ADAS and AV vehicles more competitively to market without the historic risks associated with launching new technologies into mass production using lengthy physical prototype learning cycles. This frontloading narrative combines Siemens’ capabilities that enable automakers to remain competitive as consumer demands change. Many ADAS features will evolve during the ownership of a vehicle, well after the production and initial delivery of the vehicle. The use of executable digital twins can help product developers meet the correct, up-to-date set of requirements, even as those requirements change during development and use.

Example: Sensor and Vehicle Integration

Virtually integrating sensors, vehicle dynamics, and the operational environment into the functional digital twin is required to optimize system behavior. Placing sensors upon and within the vehicle affects sensing reliability and performance. Confirming that the E/E architecture supports AV and ADAS systems without compromising performance, safety, or comfort is possible virtually. Simulating trustworthy physics-based sensor inputs and connecting the algorithms to vehicle controls can confirm successful communication and functionality between systems both inside and outside the vehicle before a physical prototype has been (or is needed to be) built. Figure 2 depicts a systems engineer exploring options as packaging, performance, and algorithmic options are considered. Even more important, early trade studies correlated to the latest product use are now possible. Compliance, through comprehensive traceability, is visible from the start assuring SOTIF (aka Safety of the Intended Function) awareness.

Figure 2—Siemens Frontloaded Ecosystems – Assessing ADAS and AV Virtually

(Courtesy of Siemens)

Several CIMdata articles summarize the expansion of MBSE driven, multi-discipline capabilities that Siemens has built. Siemens’ solutions are already enabling advances in electric vehicle engineering, systems and software engineering, executable digital twins, manufacturing planning, and operations, all contributing to accelerating every aspect of product development, production, and use. Siemens is now focusing those capabilities on frontloaded systems engineering, improving feature selection and refinement from the inception of ADAS and AV vehicle design.

Conclusion

Keeping and building trust with customers and within engineering is crucial. Frontloaded engineering drives fast-paced ADAS and AV feature development and optimization while building that trust. It is key to success in the AV market. Siemens solutions can help automotive manufacturers assure safety from ideation through architecture and feature balancing, partitioning, packaging, and planning—resulting in faster downstream development. Keeping safety requirements and regulations visible from inception enables the capability to perform continuous safety assessments. Using frontloaded engineering with safety awareness from the start keeps new ADAS/AV features within the capabilities of existing products. Siemens has a view, depicted in Figure 3, intended to help keep automakers focused on improving earlier product decisions while keeping safety standards and practices in view.

Figure 3—Continuous Safety Assessments—Critical in ADAS and AV Development

(Courtesy of Siemens)

Using a digital thread-driven systems engineering environment can enable faster ADAS and AV feature innovations and deployments without compromising safety. Adopters of Siemens portfolio enabling the frontloading narrative for systems engineering can benefit with improved, safe ADAS and AV feature introductions. CIMdata’s recommends automakers should consider Siemens’s Xcelerator technology platforms when evaluating needs and solutions for trustworthy ADAS and AV development.