Key takeaways:

- Multi-disciplinary Model-Based Systems Engineering (MBSE) is still in the early stages of industry adoption, similar in nature to the state of MCAD and MCAE technology adoption in the early 1990s.

- Early adopters of model-based engineering techniques are working to implement an integrated MBSE/MDAO approach within selected programs and domains with positive metrics of success; albeit not without the normal cultural challenges of organizational/process change and related people training.

- System architecture design and modeling languages such as SysML are maturing to meet the needs of the engineering community in designing, developing, and maintaining more robust cyber-physical systems where embedded software and electronics content is increasing at a rapid pace.

- Commercial solution providers are building integration platforms and tools such as Phoenix Integration ModelCenter and MBSEPak to bridge the gap between the currently loosely connected domains of traditional systems engineering (RFLP) and PLM/MCAD/MCAE, ECAD, and ALM.

- A new results visualization and plotting infrastructure will enable faster 3D rendering, plotting, and visualization of all the ModelCenter suite of results visualization tools for sensitivity analysis, DOE, Monte Carlo, etc. Plots and visualization tools are more professional looking, intuitive, and configurable and utilize a technology that will enable future display within web browsers. All the plotting defaults were updated based on customer feedback to make plot creation easier and more intuitive.

- An annual token licensing model in addition to the current traditional feature-based licensing. This new licensing model will give users the flexibility to run any feature within the entire ModelCenter suite of core applications including any MCAD or MBSE specialty tool plug-ins. Users can also deploy tokens to run large DoEs on highly parallel processing compute facilities such as HPC centers.

- MBSE Pak connects to SysML models today only though key parameters exposed in the Parametric Diagram. ModelCenter MBSE will enable connections to other SysML elements and model variables contained in other standard SysML diagrams.

- ModelCenter MBSE will add integrations to PTC’s Integrity Modeler 9.0 and Vitech’s Genesys6.0. Phoenix will continue to support existing integrations with No Magic’s MagicDraw, Cameo Systems Modeler, and Cameo Enterprise Architect as well as IBM’s Rational suite.

Phoenix Integration International Users Conference Highlights

CIMdata was provided the opportunity to participate in the recent Phoenix Integration International Users Conference event held in Annapolis, MD, on April 17-19, 2018. Approximately 85 engineers. Scientists, and managers from industry, government, and academia were in attendance at this 3-day event spanning the disciplines of behavior modeling and simulation, multi-disciplinary design analysis and optimization(MDAO), and model-based systems engineering (MBSE).

During the first two days of the event, speakers presented their experiences with implementing MDAO and MBSE in application domains covering space systems, aircraft, defense systems, shipbuilding, and power infrastructure. Participants were exposed to several keynote presentations on each day from industry thought leading organizations such as Airbus Defense and Space, DoD/Office of the Secretary of Defense, the U.S. Navy Naval Air Systems Command, and NASA Jet Propulsion Laboratory, as well as more in depth technical sessions during two parallel tracks focused on Phoenix Integration’s ModelCenter technologies and implementation best practices for MDAO and MBSE. Day three of the event was dedicated to hands-on ModelCenter user training and sharing of implementation best practices for both MDAO and MBSE.

Simulation & Analysis, MBSE, and PLM solution providers also participated during the first two days of the event. Commercial software and solution partners of Phoenix Integration who presented at the conference included AGI, Altair, Maplesoft, No Magic, and PTC.

Phoenix Integration also made several product announcements on the first day of the event. The current release of ModelCenter 12 is the first version to work on a full 64-bit memory architecture. This has enabled users to build and execute much larger simulation workflows containing more tool integration process steps as well as to run many more design of experiment (DoE) iterations with a minimal level of manual user interaction. A sample performance metric provided by Phoenix Integration on the impact of this new 64-bit capability was a factor of 8+ increase in the number of analysis iterations that can be completed for a complex analysis workflow, with an attendant decrease in compute cycle time of almost 50% versus ModelCenter 11.

ModelCenter 13 will be released at the end of May 2018. Major new features and enhancements will include:

Several years ago, Phoenix senior management made a sound strategic decision to focus on enabling model-based and simulation-driven systems engineering, commonly referred to as MBSE. It was clear to Phoenix then and remains clear to many in the industry today that using more advanced simulation technology early in the conceptual design of a complex system offers perhaps the greatest potential business impact and ROI for model-based systems engineering. CIMdata research and experience supports this as well. Doing many more “what if” simulations before committing to a single “optimal design” for detailed hardware and software development can translate into a significant reduction in the total systems development time and costs, as well as significant cost efficiencies throughout the entire lifecycle of the system’s deployment and usage.

In addition to defining the system-level requirements and allocating those functional requirements down to the sub-system and component levels, systems engineers typically perform various levels of trade studies to identify the most promising design alternatives to meet the customer requirements and also to identify potential key failure modes and effects analysis (FMEA). There is also a certain level of verification and validation (V&V) of the conceptual design vs. the requirements which occurs in this early stage of systems design. However, the use of more advanced simulation and analysis tools has historically been very limited due to the time required to build and execute more detailed models and the depth of expertise required across various specialty analysis domains such as structural dynamics, fluid dynamics, electromagnetics, orbital mechanics, etc. As a result, if behavior analyses are performed in this conceptual design stage, they are often performed with tools such as Excel spreadsheets and relatively low fidelity calculations including specialty custom software that links a few key performance parameters across the various engineering domain silos (mechanical, electrical/electronics, software, controls, chemical, etc.). Simulations that are performed at this stage are done to understand design trade-offs for performance, cost, weight, etc., and are used to evaluate design alternatives (A vs. B vs. C) versus V&V of the final detailed design or “as built” physical prototypes. But obviously, the higher the fidelity of simulation models that one can use at this systems design stage, the better the insights.

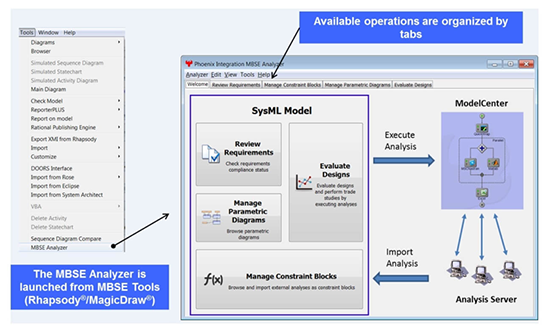

A simulation process integration and design optimization framework such as ModelCenter is ideally suited to address the gaps identified above and to provide a process and data bridge between the worlds of traditional systems engineering and the advanced simulation domains of analysis experts that consist of highly tool heterogeneous workflows. The missing piece of the puzzle was the link with the emerging modeling standard for systems architecture design- the SysML modeling language. It was with this goal in mind that Phoenix Integration developed and first released MBSEPak/MBSE Analyzer in March of 2013 (see Figure 1).

Figure 1—MBSE Analyzer Function Within ModelCenter MBSEPak

(Courtesy of Phoenix Integration)

In September 2018, Phoenix will release ModelCenterMBSE; the next generation of the MBSEPak/MBSE Analyzer functionality. Key new features will include:

Despite the substantial progress being made in bringing together MDAO with MBSE, all the presenters acknowledged the significant people, cultural, and organizational challenges that exist in adapting today’s systems engineering and simulation best practices into an integrated MBSE process framework. CIMdata finds that, as with any significant process and technology change, there will be normal cultural resistance due to existing organizational processes as well as knowledge and information silos that run counter to the collaborative nature of a systems-centric process. Ultimately, MBSE will not be successful unless it helps break down communication barriers among all the stakeholders in the product development process. Realizing the benefits of having a common systems description (i.e., a digital master model vs. documents) for today’s complex systems and even systems of systems absolutely requires a next generation digital-based approach. The U.S. Department of Defense is very vocal on this point and several high-level presenters at the event made it very clear that an MBSE approach is absolutely mission critical to ensure the continued safety and prosperity of the United States and the Western world. Ms. Philomena Zimmerman, OSD Deputy Director of Tools and Environments, stated that a digital engineering strategy is the foundation for improving agility, quality, and efficiently in DoD.

Resistance to change will also be present at the individual system engineer level. To address this reality, presenters highlighted the importance of training and education so that today’s simulation and systems engineers clearly understand the benefits that can accrue to them (How this makes my job easier.) as well as to the organization (creating successful products and profits). Providing MBSE mentors and technical support in pilot implementation projects is critical to make the systems engineer feel more productive using MBSE and MDAO as a complement to their existing tools and deep process knowledge and to ensure successful MBSE implementations, including both hard and soft benefit metrics. Also important is to make the tools as easy to use as possible for non-experts. A very promising example of this “democratization of MBSE” approach was presented at the event by the Maplesoft team. The newly introduced MapleMBSE product provides an intuitive, Excel spreadsheet-based UI for entering detailed system design definitions used in SysML authoring tools (e.g., structures, behaviors, requirements, and parametric constraints) and then integrates that spreadsheet information behind the UI with standard MBSE platforms (e.g., IBM Rhapsody, No Magic MagicDraw) for trade studies and rapid impact analysis of design changes. This novel approach does not require an engineer to use or to understand systems design tools based on SysML.

Many of the presenters encouraged the “crawl-walk-run” model of MBSE implementation, which has historically been most successful in engineering domains when introducing new processes and technologies such as MCAD, MCAE, product data management (PDM), and product lifecycle management (PLM). Initial implementation projects must be realistically scoped and staffed and need passionate internal champions in senior engineering management as well as on the program technical team that will not allow the initial MBSE implementation projects to fail due to the inevitable organizational and cultural hurdles and resistance to change. Success metrics and business benefits, both financial and non-financial, should be agreed upon up front with the team and then tracked carefully throughout the project to establish a baseline for ROI. The audience was in agreement that the early adopter engineers must become more vocal champions of MBSE and proactively promote the success stories that are achieved within their organizations as well as within their industry peers.

CIMdata has long been a proponent of process integration and design optimization (PIDO) frameworks such as Phoenix Integrations’ ModelCenter. We have also observed to our dismay that MDAO technologies have struggled over the past 1½ to 2 decades to gain mainstream acceptance within the broader PLM community, despite the acquisition of PIDO tools such as iSight by Dassault Systèmes over a decade ago and more recently HEEDS by Siemens PLM Software. In our opinion, the tighter integration of MDAO with MBSE is a natural marriage that should provide increased momentum for the adoption of model-based methods and tools within both engineering domains and, more importantly, provide tangible business benefits to the industry as well as government organizations that truly embrace model-based approaches for the “engineering of complex systems.” Everyone, especially senior management, needs to understand that achieving the ultimate benefits of digital engineering is a journey and an evolution from traditional document-centric systems engineering, not a revolution.

With their sharpened strategic focus on model-based engineering and a new senior management team firmly in place led by industry veteran CEO Jane Trenaman, CIMdata is confident that Phoenix Integration will indeed be a company that can help speed up the evolution to a model-based systems engineering environment for its customers. CIMdata will continue to track Phoenix Integration’s growth as an independent and “authoring tool neutral” company as well as the growth of the MDAO and MBSE segments within the overall PLM market.