Key takeaways:

- Tata Technologies’ wide expertise in engineering techniques and processes has given it a deep understanding of the engineering knowledge needed to support different industries.

- Tata Technologies offers a wide variety of knowledge-based engineering solutions and continually invests in expanding and enhancing them as technology evolves.

- Tata Technologies’ expertise in knowledge-based engineering spans the spectrum from knowledge reuse-related business transformation to tactical implementation of solutions for repetitive engineering tasks.

- Tata Technologies has demonstrated its robust methodology for knowledge-based engineering in several industries through client-specific solution designs and implementations.

Combating Product & Process Complexity with Knowledge-Based Engineering

The growth of connectivity and artificial intelligence is increasing design-complexity and the software content in products and product-systems at an unprecedented rate, making it increasingly difficult to ensure their dependability. Recalls and launch delays of products can be expected to become more frequent as they become more intelligent, more autonomous, and more connected. The main reason is the lack of adequate understanding among engineers regarding the potential use cases and the response of complex, software-intensive products.

Many of the dependability issues of these intelligent systems have roots at the intersection of different engineering disciplines and at the interfaces between different subsystems, where human engineering understanding tends to be low. Consequently, even if a standard, systems engineering methodology is rigorously followed, the lack of engineering experience and knowledge is likely to leave dependability issues unresolved. The dependability challenges are only likely to grow, given the relentless global competitive pressures that demand steady innovation by leveraging new technologies, while constantly cutting costs and shrinking times-to-market.

One way of mitigating the effect of lack of engineering experience and knowledge is through knowledge-based engineering (KBE), wherein information about past product performance, including failure modes, can appropriately be captured and provisioned for reuse in future developments. The knowledge reuse enabled by KBE can accelerate innovation while ensuring dependability and improving operational efficiency through application all along the product lifecycle.

As product complexity increases, with increasingly complex interactions between mechanical, electronic, and software components, the process of engineering such products also becomes more complicated. So much so, that training new engineers, as well as reusing existing designs becomes more difficult, when compared to simpler systems.

Traditionally, KBE was closely associated with geometric modelling in CAD systems, allowing geometry to be rapidly created using sets of rules describing steps in the process. However, in the context of connected intelligent products, KBE applications should be viewed as integrated systems solutions, with dynamic links to the governing knowledge base that can be reconfigured as new information becomes available and requirements evolve over the product lifecycle.

The goal of KBE is not only to automate engineering tasks, but also to imbed knowledge into the product model. This knowledge may include functional knowledge, manufacturing knowledge, and process knowledge. However, many organizations only implement design automation capability, which is restricted to functional automation but call it knowledge-based engineering. In general, design automation is a tool for automating well-defined, sequential steps in a product development process, reducing time to complete the task, thus improving productivity and cost effectiveness. KBE, on the other hand, is a higher-level implementation, incorporating methods for knowledge acquisition, modelling, and management. KBE applications typically require additional levels of development and understanding of not only the problem domain, but the organizational context within which the product will be used. Goals of KBE systems are intended to produce robust automation for processes that can adapt well to new situations, whereas a design automation system would not be able to handle scenarios that have not been hard-coded into the product’s design.

KBE should provide the capability to:

- Automate processes in product development for reducing time and cost

- Ensure consistent quality of outputs from engineering processes

- Verify designs against standards

- Capture engineering knowledge for later reuse

- Retain knowledge of domain experts

To provide those capabilities, the KBE systems must be able to:

- Reconfigure rules and outputs based on new inputs

- Handle new known and unknown problems

- Derive new rules automatically from old rules based on input changes

- Provide high-level commands that invoke several sub-processes

Very often the “so-called” KBE solutions tend to be design automations, which are standalone programs that automate engineering tasks but lack the dynamic nature of “true” KBE applications. Rules tend to be hard-coded, requiring updates to source code when changes in data and requirements occur. However, due to the relative level of detail of design automation applications, the development and deployment timescales tend to be much shorter, thereby allowing working solutions to problems to be delivered to engineers quickly.

The unbridled design complexity that connected intelligent products are bringing to companies, demands a strategically thought out transformation of engineering processes for the introduction of a “full scope” KBE based on a systematic development and implementation of a roadmap. In other words, a strategic consulting project needs to take place before design and implementation of the KBE. This demands a capability to assess a business from the long-term KBE development and implementation viewpoint, with the ability to assess the implementation as the business transformation takes hold systematically.

In CIMdata’s opinion, for the implementation of KBE systems for developing complex, connected intelligent products, one does not only need a large number and variety of tools for design automation, one also needs to consider the high-level dynamic capability of capturing and reusing knowledge that adapts as new knowledge appears.

Tata Technologies’ Expertise in Transforming Businesses with Knowledge-Based Engineering

CIMdata has found that Tata Technologies can deal with a number of typical product development challenges using its KBE capability. Some of those challenges include: managing complex design processes, automating repetitive tasks, capturing design intent in parametric modelling, integrating multiple design processes, assimilating engineering knowledge, deriving mathematical models, and managing products undergoing configuration change.

Tata Technologies’ eight-step KBE lifecycle, which includes Identify, Capture, Analyze, Design, Develop, Integrate, Deploy, and Improve, translates into a process for developing KBE applications that resembles typical software application development, integration, regression testing, verification, validation, and release. Additionally, the KBE applications are developed by following an Agile development methodology to reduce the development cycle time.

CIMdata is aware of the different modeling approaches that Tata Technologies uses for KBE, and those modeling solutions include, parametric, programmatic, function-based, web-based, ontology, case-based, and artificial intelligence (Figure 1).

Figure 1—Tata Technologies’ Knowledge-Based Engineering Solutions

(Courtesy of Tata Technologies)

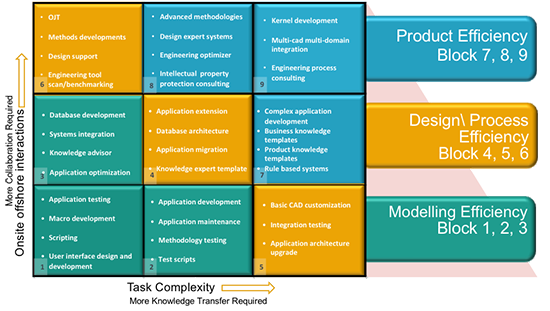

CIMdata notes that Tata Technologies’ process of developing a KBE solution for a client essentially comes in three flavors: KBE Scan, KBE Development, and KBE Comprehensive. The KBE Scan solution is an assessment layer where Tata Technologies gains an understanding of the client’s product development process, identifying knowledge. The KBE Development layer is where the opportunities for automating, integrating, and customizing product development processes are explored. In the KBE Comprehensive layer, Tata Technologies develops a detailed framework and map that define a knowledge management level KBE that has the potential to realize strategic transformation. The process of business transformation based on KBE can also be seen in terms of three stages on a 3 x 3 grid of collaboration versus knowledge transfer (Figure 2).

Figure 2—Tata Technologies’ Approach for Applying KBE to Achieve Business Transformation

(Courtesy of Tata Technologies)

Tata Technologies has wide expertise in designing and implementing KBE solutions in the industry. Some examples of KBE applications are:

- Design checks and drawing creation application for inspection of tube components for a leading tubing manufacturer

- Automated placement of different types of fasteners based on structural material for a leading aerospace company

- An organizational data core and insights platform for an aerospace OEM to enable a transformational journey to an insights-driven business

- Automated alignment of brackets, clips, and structures for a leading aircraft manufacturer Part generation and drawing creation of clips for a leading automotive supplier

- Automatic generation of belt brackets in NX and CATIA based on specified design criteria

- Suspension geometry data analysis for MacPherson front suspension for an automotive OEM

- Compute and extract bending points of tubing in 3D and create a bending-table in drawings (2D) in CATIA

- Create and manage welds in 3D and export and import weld files from various legacy systems

- Automate electrical harness design process to reduce time and speed propagation of design change to manufacturing

Summary

Over the years, CIMdata has kept track of the progress of knowledge-based engineering solutions, especially as a potential solution for dealing with the dependability issues of products that leverage IoT and artificial intelligence to function autonomously or optimize and repair themselves. In CIMdata’s opinion, many offerings, although called KBE solutions, are in the realm of design automation and not truly related to engineering knowledge capture and reuse. In other words, those design automation solutions can produce savings in performing repetitive tasks quickly and correctly, but they cannot help in resolving design issues that stem from improper engineering related to product complexity.

CIMdata believes that the engineering of complex, software-intensive products that leverage IoT and artificial intelligence for delivering more innovative functions needs a systematic way of converting implicit knowledge of subject matter experts into explicit machine-readable knowledge, so that it can be used in the right context of product development. In CIMdata’s opinion, such dynamic high-level representation of knowledge, which can be updated with changing design needs, demands a strategic long-term view of product development in an organization. It also requires a detailed assessment of the current product development processes, followed by the development of a realistic roadmap to the desired KBE state. Such a roadmap must be based on assumptions about adoption of knowledge-based engineering that are consistent with the rate of transformation that is feasible in each specific organization.

Tata Technologies’ capability in knowledge-based engineering covers a variety of modeling approaches, as well as process evaluation methods for identifying the best solution for the particular product development landscape. CIMdata is convinced that Tata Technologies’ with its expertise in KBE tools and methods, and KBE-related business transformation can help companies in different industries to successfully take on the transformational journey to become learning organizations that can develop dependable innovative new products, while improving their operational efficiency. Tata Technologies has broad expertise in helping businesses design and develop, electronically-controlled software-intensive products, which it is translating into KBE tools for future IoT and autonomous systems applications.