Key takeaways:

- Hannover Messe, April 2018, proved a perfect stage for Siemens AG Group and Siemens PLM Software to prove what’s available with Additive Manufacturing (AM). Siemens, the largest of 5,000 exhibitors covering 27 halls, had significant presence in both Hall 6 for Digital Factory solutions and Hall 9 for Integrated Automation, Motion & Drives.

- Customers expectations of AM are changing; they are now asking Siemens what’s possible with AM in production. Siemens is well positioned to help customers answer this question.

- Proof that AM is turning industrial and is all digital came from a visit to small engineering services firm Toolcraft GmbH from Georgensgmünd Germany. Using Siemens NX and Metal Laser Melting (MLM) equipment, they serve a global customer base including leading US house-hold name aerospace companies.

Analyst Event

A group of AM industry analysts from around the world were privileged to attend a series of events built around the annual Hannover Messe industrial equipment fair in Hannover Germany in April 2018. The event kicked off with presentations from a diverse set of leading speakers such as Prof. Dr.-Ing. Claus Emmelmann, CEO, Fraunhofer IAPT, a legendary German research institute, Mr. Joe Inkenbrandt, CEO Identify3D, who offers AM security solutions, and Mr. Phil Hatherley, General Manager, Materials Solutions, a leading AM material consultancy and pre-production services company.

The Voice of the Customer

Mr. Bob Jones, EVP Sales and Services at Siemens PLM Software, shared the new voice of his customers to illustrate that the industrialization of AM is getting traction in industry. He believes that AM is “about to take off” given two significant indicators that CIMdata consulting activities validate:

- Convergence of technologies. End-to-end software solutions that allow customers to design, simulate, and optimize all aspects of an AM design throughout its lifecycle, powered by cloud services, accessible via various hardware platforms and scalable through a global ecosystem of AM specialist product and services organizations.

- Organizational. Organizations that are seeking to be more competitive in a global marketplace are looking to AM to leapfrog their competition. Customers are now asking Siemens what’s possible with AM and how to make end-use industrial quality AM products.

Latest State of AM technology

Professor Emmelmann, gave an insightful presentation titled “The Next Opportunities for Industrial 3D Printing,” during which he gave an overview of the materials, technologies, and equipment currently available in the AM landscape, as well he shared new opportunities for AM parts and processes for industrial use.

Professor Emmelmann first highlighted some of Fraunhofer’s significant recent accomplishments and collaborations including the first additively manufactured metal part for civil aircraft, the world’s largest hybrid functional assembly based on 3D printed thin walled titanium metal components for the Bugatti Chiron[1] hyper-sports car, and various awards and industrial certifications.

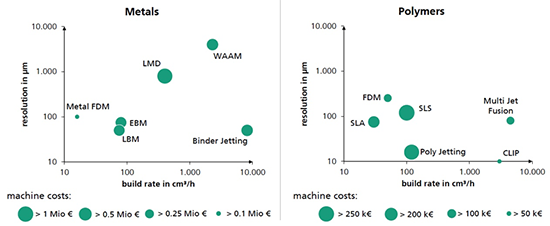

Fraunhofer assist industrial companies with guidance in AM design through manufacture of AM products. They help choose print technologies and materials as well as conduct actual pre-production validation prints using their in-house equipment. Figure 1 compares metals and polymers against two axes: build rate in cm3 against resolution or fidelity in micro meters. This is a convenient way to choose a material suitable for the intended end-use part. For example, if build rate or speed to produce parts is critical, then multi-jet fusion (polymers) or Binder Jet (metals) might be the best choice. If resolution is critical, Wire Arc Additive Manufacturing in metals might be the best choice.

Figure 1—Comparison of Additive Manufacturing Technologies—Build Rate Compared to Resolution

(Courtesy of Fraunhofer IAPT)

AM Digital Security

Mr. Inkenbrandt addressed the critical issue of security. Critical because AM files are all digital and contain topology and geometry, manufacturing process instructions, and material definition. Mr. Inkenbrandt outlined some of the threats to security of AM data fields throughout the lifecycle starting in engineering through manufacturing to distribution. He highlighted the various systems and machines involved throughout that journey; each a point of failure due to threats from either internal attacks (bad engineer, rogue IT staff member) or external attacks (corporate espionage or counterfeiters). Threats come in various forms from IP theft, malicious modification, and transaction falsification each of which is very harmful to the industrial or military entity but also potentially to the public e.g., part failure in a commercial aircraft. Mr. Inkenbrandt, who has a background in hardware and software engineering, protocol security, and intellectual property licensing outlined the capability of Identify3D’s solution set to mitigate these risks not only while data is in transition, but when static. Key precautionary actions include:

- Prevent distribution node access to manufacturing workflows

- IT audits and certification

- Standardized (and secure) technical data package (TDP) structure that is compatible across systems

- Enforcement nodes in certified manufacturing facilities

- Certification tracking and enforcement system

With globalization of supply chains and frequent news about corporate espionage, concerns over engineering data security is rising in both commercial and military sectors. This, together with the fact that AM engineering data is entirely digital (topology and geometry, manufacturing process, and material), AM manufacturing data security is a critical issue needing attention. Sadly, industry adherence to strict security measures governing AM data security is generally lacking, even in companies doing advanced industrial AM production.

Additive Manufacturing Network

Mr. Robert Meshel, Director of the Siemens’ Additive Manufacturing Network[2] initiative, outlined the online collaborative platform designed to accelerate the use of AM in the global manufacturing industry. Mr. Meshel set the context for the AM Network by describing the complex supply chain relationships which support modern manufacturing today. Whether for design, manufacture, or servicing, manufacturers rely on a diverse ecosystem of a large number of small players. Industry agnostic, the AM Network connects the manufacturing ecosystem to accelerate AM industrialization. What this means in practical terms is that the engineering designer of AM products can access the following throughout the design-manufacture lifecycle:

- Subject Matter Experts (SMEs) in AM to guide and validate design and manufacturing choices

- Material library and material fit-for-purpose decision making

- Software tool suppliers for design, simulation, manufacturing nesting, costing, etc.

- AM machine makers

- Turnkey AM service providers

Beyond facilitating connections between AM designers and suppliers, the AM Network also manages the commercial process including supplier contractual status, SME rates and fees, order management, and operations management. This capability enables end-to-end traceability and repeatability; essential fundamentals of any industrial manufacturing process.

Clearly more than a library of commodity components, the AM Network is a very comprehensive cloud-based commercial ecosystem hub, designed specifically to support the needs of industrial AM manufacture. Siemens PLM Software, being part of Siemens AG Group, the 170-year-old industrial technology giant, is well positioned to tap into the broadest and deepest industrial eco system available to support the industrialization of AM.

Hannover Messe Exhibition

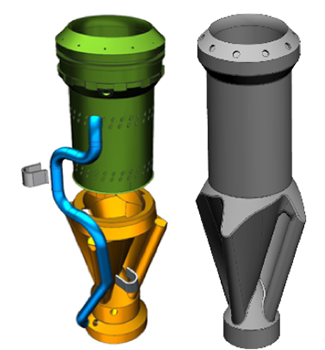

Following the presentations to analysts, we were escorted to Hall 9 in the Messegelände exhibition area; one of 27 exhibition halls, to be hosted by Siemens AG (Siemens PLM Software’s parent company) to see a series of presentations showcasing Industrial AM. Hall 9 hosts for Integrated Automation, Motion & Drives so was full of physical machines of all types and sizes. Of particular interest was “Insights into Industrializing High-End Metal 3D Printing,” where original, traditional, and redesigned, AM and traditionally produced metal components were compared and contrasted. This offered tangible proof, supporting the presentations in the morning sessions, that real industrial AM work is being achieved in industry today, as shown in Figure 2.

Figure 2—Siemens’ Gas Turbine Burner

13 Parts Conventional Design (left) Redesigned for AM as a Single Part (right)

(Courtesy of Siemens PLM Software)

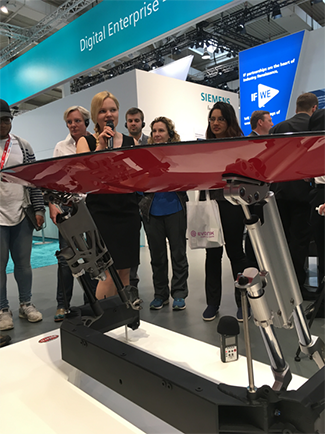

After a series of showcase exhibits, we were escorted to Hall 6 which is for Digital Factory solutions like CAD, CAE, and PLM. This is where Siemens PLM Software, a business unit of the Siemens Digital Factory Division, showed their collective software capabilities for end-to-end digital engineering. Although now in the software exhibition hall, there was still plenty of physical machinery to offer tangible practical proof of the software working in industry. An extraordinary example of high performance Industrial AM was the Bugatti Chiron exhibit. See Figure 3. The rear spoiler support struts were redesigned from the already high performance (right side) to the more advanced AM design (left side). The project was a collaboration of Siemens using the NX AM integrated software solution, Fraunhofer IAPT for AM production, and Bugatti. Results of the AM version compared to the original are significant:

- Innovation process was 10X faster

- Reduction of aerodynamic drag

- Lightweighted by 50%

- 3D printed hollow and thin-walled bionic titanium metal components

- Ceramic-coated, wound, high-modulus carbon fiber tubes

Figure 3—Bugatti Chiron—Left is Rear Wing Actuation System as Redesigned Using AM, Right Side is Original Design

(Courtesy of Siemens PLM Software)

Collectively, the combination of exhibits in halls 9 and 6 offered compelling proof that Siemens PLM Software, Siemens Digital Factory Division, and Siemens AG collectively provide superb end-to-end capability for production of industrial quality AM products.

Toolcraft GmbH Proof Point

The next morning, we left Hannover and traveled by high-speed train to Georgensgmünd to visit Siemens’ customer Toolcraft GmbH, a thirty-year old specialty engineering services shop with a mix of traditional and AM equipment. Commencing AM production services in 2005 when the market for industrial AM production was immature, Toolcraft continued to invest despite weak demand from the industrial market. In 2011 as demand improved, Toolcraft added AM production capability, but still operated it as an isolated AM production-only facility. In subsequent years Toolcraft developed an end-to-end continuous digital process chain starting with customer requirements, design data import, and optimization for AM using the Siemens’ NX AM software solution including topology optimization, lightweighting, pre-processing, distortion simulation, and production inspection. The entire process is reversable to allow for fast changes triggered at any stage throughout the lifecycle, to be fed back into design.

From the early investment in AM to today, there has been a significant shift in both capability and demand. Revenue from 2011 to 2017 has risen from an almost rounding error in 2011 to a significant share of overall company revenue in 2017.

For more information on Toolcraft see: https://www.youtube.com/watch?v=9BpLX4HgmJk

Closing Remarks

CIMdata came away from the short action-packed tour impressed. The presentations on day one from Siemens and partners outlined the vision of what’s possible today with Industrial AM production. The tours of Hall 9 and 6 expanded the vision by showing how Siemens PLM Software leverages the strength and commitment of parent, Siemens AG group, and are not merely a standalone maker of PLM software tools. To book-end the tour, Toolcraft, a small engineering services company in southeast Germany, was real proof that industrial production of AM parts is happening now.

While at Toolcraft and walking through the final production inspection area I saw high-end aerospace parts on the shelf labeled with leading US aerospace company names. These were very high quality ready-for-service aerospace engine components, AM designed, printed, and tested, ready for shipment to the US. I thought to myself, why is it that a tiny engineering services company in rural southeastern Germany is doing serious industrial quality AM production work for US aerospace house-hold brand name companies? The answer requires another commentary!

[2] See: https://additive-manufacturing-network.sws.siemens.com/.