Key takeaways:

- Teamcenter X is a fully functional, future-ready, SaaS solution built using microservices and standard cloud services for companies of all sizes, across industries.

- Instant-on access to Teamcenter X enables fast deployment and quick expansion when needed.

- Teamcenter X enables a comprehensive Digital Twin including mechanical, electrical, and software across the extended enterprise and the complete product lifecycle.

- The common code base between Teamcenter X and Teamcenter provides the ability to migrate tailored and/or customized Teamcenter instances from on-premises to cloud delivery when needed and at the customer’s pace.

Introduction

Manufacturing enterprises across all industries are facing a myriad of challenges that impact most, if not all, facets of their business as products continue to become more personalized, more complex, more capable, more connected, and interconnected. This is driving the need for more intelligent, flexible product development environments, more responsive production and service capabilities, as well as the need to enable and manage extended lifecycle value chains. As global competition continues to increase and digitalization technologies rapidly mature, manufacturers have recognized that undergoing digital transformation can deliver quantifiable business benefits in multiple areas. Manufacturers are also recognizing the value of the digital thread and comprehensive digital twins as concepts that can be used to enable true end-to-end lifecycle innovation and optimization.[1]

PLM enabling technologies and solutions have evolved significantly over the past few decades, bringing new digital capabilities such as driving a virtual model with simulation and/or field data to predict product behavior and provide performance insights directly to the development process and across the product’s lifecycle. This evolution is enabling enterprise-level digital transformation and driving enterprise level product and process innovation. Executives are recognizing the positive impact PLM can have in helping their companies meet its business potential. However, to address today’s business challenges, PLM environments must enable rapid evolution in all areas of the business—market requirements, product complexity and mix, distributed production and service, regulatory compliance, etc.

In reality, most PLM environments reviewed by CIMdata have rarely been used effectively across the extended enterprise as originally envisioned. This is partly due to technical limitations but also due to the lack of process reengineering and a myriad of organizational issues. In a CIMdata position paper “PLM is Hard,[2]” key issues with some PLM solutions include: (1) they weren’t architected and implemented for the enterprise; (2) the solutions were designed by engineers for engineers; and (3) the implementations did not take full advantage of the chosen PLM solution’s capabilities, architecture, and/or technologies. To effectively support today’s complex, heterogeneous, extended enterprise value chains, PLM solutions must support multi-domain people, process, and technology requirements, across extended, heterogeneous value chains, and easily adapt and grow as the enterprise evolves over time. This requires a modern, platform-based PLM data and process management backbone.

Characteristics Needed in a Modern PLM Solution

To address the challenges described above, companies need to implement a modern platform-based PLM environment and establish a full lifecycle digital thread. Modern architectures enable an enterprise to more easily adapt their technology, information, and supporting applications and environment to meet changing business needs. Implementing this type of environment exposes data in context making the configuration of personalized applications easier and more sustainable.

As previously stated, today’s PLM solutions must be built on a flexible, adaptable, scalable architecture designed to evolve and grow as a company’s needs change. It should have the ability to be delivered on multiple IT infrastructures from on-premises to the cloud so that companies can implement and scale (in capability, locations, and user count) as demand dictates. Cloud-delivered solutions address these issues by providing the ability to scale globally, on demand while maintaining high availability and being delivered on multiple types of user devices, e.g., smart phone, tablet, laptop, desktop. Further, cloud infrastructure providers such as AWS and Azure have incorporated very strong security protocols within their services to ensure maximum IP protection.

The solution must provide easy-to-use applications that solve complex problems and address various business needs. PLM spans much more than just engineering and must enable creation of an open ecosystem of connectivity with other business systems, applications, partners, and connected devices, whether run on-premise, in the cloud, or at the edge. Such open ecosystem connectivity is required to enable implementation of a true lifecycle digital thread and a comprehensive, actionable digital twin as described as follows:

- A digital thread is a communication framework that connects data flows which can be used to produce an integrated, holistic view of an asset’s data from physical and virtual systems (i.e., its digital twin) throughout its lifecycle across traditionally siloed functional perspectives.

- A digital twin is a virtual representation (i.e., digital surrogate) of a physical asset or collection of physical assets (i.e., physical twin) that exploits data flow to/from the associated physical asset(s), continually evolving as it accompanies its real-world physical companion throughout its lifecycle.

A comprehensive, actionable digital twin possesses the required accuracy and fidelity to predict physical behavior and even optimize the actual performance of the physical asset, whether it is a product or process, it represents. Implemented fully, the digital twin thus represents both the entire history and the current state of all enterprise assets and can be used to accurately simulate past and future operational scenarios.

Additionally, an effective PLM solution must be able to be “personalized” or tailored for corporate, business unit, and functional domains—and even individuals—to deliver consistent, contextually relevant, user experiences all while enforcing appropriate industry, business process, and IT standards across the extended enterprise value chain.

In CIMdata’s view, to fully support the wider initiative of digital transformation, manufacturing companies need to enable a holistic Manufacturing Enterprise Innovation Platform[3] (MEIP) that creates and manages a digital thread that enables digital twins by spanning the enterprise from end-to-end across all lifecycle phases. It needs to be built on a modern PLM-enabling Product Innovation Platform foundation that has tightly integrated authoring and analysis applications that create and maintain a comprehensive and actionable set of digital twins. As CIMdata discussed in a commentary last year,[4] the Siemens Xcelerator portfolio is an excellent example of the technologies and solutions required to implement an effective MEIP. Within that portfolio, Teamcenter X is a foundational PLM solution and is also used to implement a Product innovation Platform that can support an extended enterprise.

Siemens Teamcenter X–Delivering a Modern PLM Solution

Teamcenter X is a significant evolution of Teamcenter. It incorporates the defining characteristics of a modern PLM solution. On an infrastructure level, leveraging cloud services including multitenancy and microservices are basic requirements. Key capabilities include a comprehensive variant configurator to manage complex products and product families, broad and deep capabilities to enable multi-BOM, multi-CAD, and the ability to define an end-to-end digital thread as well as a comprehensive digital twin. All are critical for business process improvement and optimization.

Modern Cloud Platform

Teamcenter X is a fully functional, future-ready, SaaS solution for companies of all sizes, across industries. Teamcenter X leverages multitenant industrial components, such as authentication and file storage microservices, from the Siemens’ Mendix low-code application development platform. It is a cloud implementation that supports instant on PLM with strong security, grows on demand, and is maintained and updated by Siemens.

Cloud services used by Teamcenter X are built to scale and size as needed, and are used for critical PLM components, for example, Teamcenter X uses the AWS RDS cloud database service. This cloud architecture enables Teamcenter X to scale to any required size while continuing to deliver the always-available, fast performance demanded by today’s users, with the big benefit of always being up to date.

Instant-On and Grows as Needed

Teamcenter X provides instant-on PLM, simplified solutions packaged with best practices, ease of onboarding users quickly, and the ability to grow an enterprise’s PLM environment when ready. With the SaaS delivery, Siemens drives the deployment of Teamcenter X, taking care of all software and hardware requirements, operations, maintenance, and upgrades. Customers have access to training and Siemens’ consultation to ensure users have everything they need to get up and running quickly.

Siemens offers functional and domain-specific packaged solutions for Teamcenter X that incorporate best practices based on years of industry experience. These solutions contain preconfigured capabilities, such as workflows and CAD integrations that are intended to simplify PLM processes, without taking away the ability to address complex scenarios. Teamcenter X is positioned for growth. At any time, customers can opt to add-in more Teamcenter business and engineering solutions (e.g., Product Configurator, Capital Asset Lifecycle Management, and Requirements Management) to fit new or evolving functional needs.

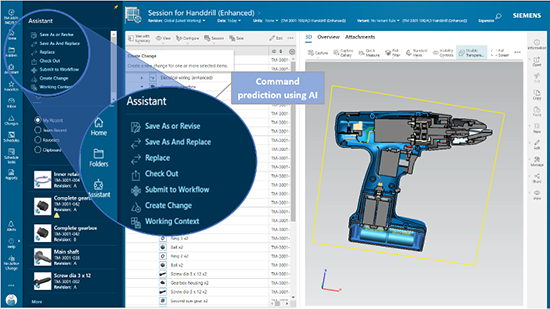

CIMdata’s experience with its customers shows that ease of use is critical to achieving maximum productivity and adoption of any PLM environment. With Teamcenter X, users are provided with an easy-to-use interface that helps to onboard users and increase their productivity. Teamcenter Assistant, which is part of the user interface, incorporates artificial intelligence (AI) elements like command prediction that learns as a user works, reducing mouse clicks by up to 30%. This AI-driven interface can help users across the enterprise get up and running quickly, as well as work smarter. The following figure illustrates Teamcenter Assistant.

Figure 1–-Teamcenter Assistant Uses AI to Guide Users and Reduce Mouse Clicks

Figure 1–-Teamcenter Assistant Uses AI to Guide Users and Reduce Mouse Clicks

(Courtesy of Siemens Digital Industries Software)

Additionally, Teamcenter X can be personalized by working with Siemens and using Mendix to rapidly create company-unique composite applications across their extended enterprise. This enables a company, for example, to maintain a tailored interoperable, highly accessible, open ecosystem of applications and models connected to a comprehensive digital twin.

Comprehensive Digital Twin

Teamcenter X supports a comprehensive digital twin by managing electrical, mechanical, and software components in a single, multi-domain Bill of Materials across all the functional modules that are part of the Teamcenter suite. It is also designed to enable companies to create and maintain a comprehensive digital twin that encompasses product development, manufacturing, and service operations using Siemens tools or other best of breed applications via its open ecosystem and integration capabilities.

Evolve at Customer’s Pace

It is important to note that Teamcenter X is Teamcenter—all the modern advancements made for Teamcenter X are made for all Teamcenter customers, on-premises and on-cloud. Also, on-premises/cloud hybrid environments can be configured so customers can migrate to the cloud and/or add new Teamcenter X functional modules at their own pace.

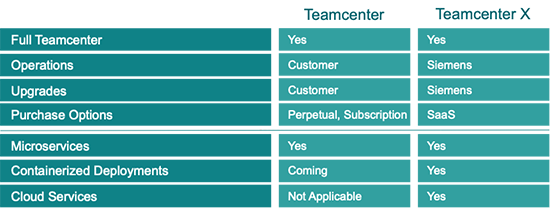

Figure 2 provides a high-level comparison between Teamcenter and Teamcenter X.

Figure 2––Comparing Teamcenter X and Traditional Teamcenter

Figure 2––Comparing Teamcenter X and Traditional Teamcenter

(Courtesy of Siemens Digital Industries Software)

CIMdata is impressed by Siemens’ claim that, by working with Siemens SaaS Operations, customers will be able to migrate and support company-specific customizations within Teamcenter X, and we look forward to hearing about customer experiences.

CIMdata believes Teamcenter X is a major evolution of the Teamcenter suite providing new delivery and growth options that should enable Siemens’ customers to become more important to their value chain of partners and optimize and maximize their PLM investments.

Conclusion

Effectively supporting today’s complex, heterogeneous, extended enterprise value chains, requires a modern PLM solution built on an open, flexible, adaptable, scalable architecture designed to evolve and grow as a company’s needs change.

Teamcenter X is a modern, complete, fully-functional, SaaS implementation of Teamcenter designed to enable companies to create and maintain an interoperable, highly accessible, and open ecosystem of applications and models. Teamcenter X’s cloud delivery enables companies to startup fast, grow and scale as their needs demand, all within a highly secure environment, managed and updated automatically by Siemens.

CIMdata views Teamcenter X as a modern PLM solution that can enable companies to effectively create a comprehensive, actionable digital twin and manage the complete product lifecycle from creation through production and service across a heterogeneous value chain. Manufacturing enterprises facing today’s complexity challenges should include Siemens Teamcenter X in their evaluation of solutions for implementing a modern PLM environment.