Key takeaways:

- Product Definition in the automotive industry is continuous, expanding to include vehicle use.

- Integrated Model-Based Systems Engineering (MBSE) provides engineers the ability to see the effects in context of a vehicle’s multiple architectures, including off board support services.

- Automotive development processes and modelling methodologies are evolving including architecture and usage insights.

- Siemens’ Software & Systems Engineering (SSE) Product Definition capabilities enable an integrated MBSE environment.

Product Definition Must Evolve

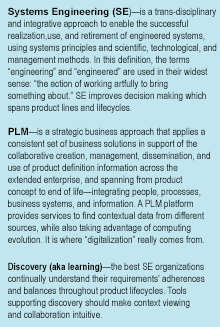

In the world of automotive vehicle development, product definition has historically been an early activity done with a product’s charter—its scope and performance requirements driven by the voice of the customer. Vehicle development and operations in the future need to utilize a modern and integrated PLM environment that enables holistic systems engineering (SE). As all disciplines making and servicing vehicles discover new insights, systems engineers will continuously explore the vehicle architecture and performance to better comprehend and minimize risks. But to be successful, SE must be integrated and used throughout a vehicle’s life. CIMdata has defined and encouraged industry leaders to embrace a system of systems mindset and the need for a comprehensive and integrated PLM ecosystem to help manage it all. Note our definitions for SE, PLM, and Discovery.[1]

Today’s modern automobiles have an architecture that allows future features to be added and enhanced, often after mass production. Many of these features are solely enabled by software. Some of the software is off board in services for infotainment and navigation applications. As cloud computing and consumer demand for autonomous driving expands, system boundaries may change, further increasing systems complexities. Automotive products are just starting to take advantage of this connectedness.

A broader product definition done well is needed as vehicle systems complexity grows across their lifecycles. This means that product definition is no longer just an early phase of a product’s lifecycle (i.e., during traditional development), rather it is becoming an ongoing activity that needs the skills of lifecycle-focused systems engineering and must include multiple discovery and learning cycles. Additionally, with the advent of almost free product upgrades with new features implemented in software, it is critical to understand how a new feature plays with the existing product already in a customer’s hands.

Modeling future vehicles with their applications will require improved tools, especially centered on systems engineering. In fact, we expect more and more disciplines will use systems engineering models to answer the question: “Will our existing products in customer’s hands work with the new feature?” Thus, product definition is not just part of vehicle conception, but also occurs throughout the vehicle’s life. Figure 1 emphasizes this operational lifecycle model-based approach and the fundamental shift needed by the automotive industry.

Figure 1—Model-Based Approach Bridge Disciplines

Figure 1—Model-Based Approach Bridge Disciplines

(Courtesy of Siemens)

All engineers need to answer questions about robustness and safety of an in-field product upgrade. The upgrade could even be in the cloud that a vehicle relies on (i.e., consider navigation routing updates and real-time feeds for traffic flow). This started as a feature inside the vehicle, with a cumbersome upgrade process rarely done. Now it is always up to date. The feature comes from a third-party, but the navigation display is still in-vehicle. This is an example of changing system boundaries during the operational lifecycle. As advanced driver-assistance systems (ADAS) features in vehicles continue to expand and autonomous vehicles enter the marketplace integrated MBSE tools are needed to aid in keeping vehicles continually and robustly up to date. Multiple disciplines will use MBSE models and methods to improve decisions—this is crucial to help manage increasing vehicle systems complexities.

SSE Product Definition Aids Managing Vehicle Complexity

Defining a vehicle, assessing it continuously, and re-defining it as usage occurs is the focus of Siemens Digital Industries Software’s (Siemens) SSE Product Definition solution. Siemens realizes the need to use MBSE more broadly and to make sure an extended enterprise’s PLM ecosystem facilitates this. While SE experts develop SysML models, discipline experts in software, electronics, and mechanical engineering will use these “understanding” models to improve their designs and changes. Ideally, they will do this in a user experience (e.g., visualization) they already know. The product definition work is expanding beyond requirements and parameter management to include features, architecture, and product lines and even service upgrades. Siemens’ SSE Product Definition capabilities address these challenges as summarized in Figure 2.

Figure 2—SSE Product Definition Capabilities

Figure 2—SSE Product Definition Capabilities

(Courtesy of Siemens)

Already, some automakers use motion models with mechanical packaging designers to make sure motion sensors are placed into the vehicle at the best location for safe operations. In the not-so-distant-future, manufacturing assembly and wiring harness designers will work collaboratively, in real-time, making sure the wiring placement is producible, reliable, and serviceable. Being able to view the effects of a proposed change improves product robustness. Reviews for choosing amongst alternatives will accelerate and improve as all disciplines interact with models—coordinated by the system-understanding framework. This framework needs PLM and integrated MBSE to provide interactive views for authors, investigators, and decision makers. A common, evolving understanding will lead to robust products.

Some future vehicle complexity will undoubtingly come from changing system boundaries. With an established SE framework of a product in its operational environment, as these system boundaries change, a product manager could quickly assess the changing environment interactivity as the SE models improve through field experiences. Performance engineers will convey what the customers are telling them by upgrading the performance digital twin, a group of models, which can then be managed by system engineers and others to assess risk and plan product upgrades. In the future, models will no longer be constructed by decision point with modelling experts but will be configured on demand using the best insights from the field. Figure 3 graphically depicts the domain of Product Definition used by all disciplines and managed by systems engineering.

Figure 3 – SE Manages Product Definition

Figure 3 – SE Manages Product Definition

(Courtesy of Siemens)

CIMdata has commented previously on consistent configuration use within the electrical development ecosystem, Capital.[2] Vehicle configuration capability is a hallmark of the automakers. It was perfected for supply chain management and efficient mass production. The rules of configuration provide a basis for parts, subsystems, logistics, and their planned volumes. What drove corporate efficiency in manufacturing can also apply to engineering and information technology (IT). The architecture tools need consistent, real-time product and service configurations. Siemens’ overall approach and their Product Configurator are the needed advances to enable on-demand comprehensive digital twins—accessible and always accurate. One can imagine using the same capability for a vehicle in use to understand a new failure and more quickly explore likely causes. The on-going root cause investigation is improved with every sample of data from the field, which thanks to connectivity (aka IoT) technology, is now near real-time. No more waiting and no more confusion on the specific vehicle configuration when sampled.

Siemens’ advancements on the way to integrated MBSE are enabling continuous product definition as shown in Figure 4. By supporting proven exchange standards, an ability to easily integrate across the extended enterprise is realized—creating open ecosystems allowing external tools and data sources to be seamlessly integrated. CIMdata will elaborate on this in a future commentary on Connected Engineering.

Figure 4—Software & Systems Engineering Pillars

Figure 4—Software & Systems Engineering Pillars

(Courtesy of Siemens)

Summary

Over the last several years, SE has expanded with the power of computing, allowing faster exploration of solutions and safety margins of candidate designs. Simulation accuracies continue to advance as AI/ML techniques are applied. A common product configuration engine used across mechanical and electrical disciplines is a cornerstone of modern PLM platforms. It provides an accurate digital twin that improves vehicle design, manufacturing, and usability understanding. The combination of integrated MBSE tools and methods with consistent vehicle configuration enables a comprehensive digital twin, always accurate to the latest discoveries.

Siemens continues to build a comprehensive set of solutions across the engineering and other lifecycle disciplines. Engineering skills expanding beyond their original disciplines to better understand the effects in other domains will improve vehicle quality. Improved understanding will improve robust vehicles and ADAS services, even as systems evolve for autonomous vehicles after their mass production.

Siemens evolving SSE Product Definition solution enables the evolution of SE beyond a silo of experts to a competitive advantage practiced by most of the organization. Their intelligently integrated PLM ecosystem is realizing a comprehensive product development environment.

CIMdata recommends that companies consider Siemens’ SSE portfolio of solutions, especially Product Definition driven by integrated MBSE, when evaluating and/or migrating current vehicle development solutions. Roles and skills will need to change and expand to take advantage of these tools. As computers are pervasive in vehicles today and tomorrow, a comprehensive, integrated, and multi-disciplinary product development environment is essential.