In today’s competitive business environment, companies must deliver more innovative products and services, reduce costs, improve quality, and shorten time to market, while achieving their targeted return on investment (ROI). To reach these goals, businesses must continually improve how they operate in order to become more efficient and productive. Innovation must occur in all dimensions—product, process, and organization to allow companies to present the right products to the right markets, at the right time, for the right cost (the money spent to develop the product) and right price (what the customer pays).

Lack of innovation may have serious consequences, as shown in the following example. After ten years of successful operations, a satellite owner decides to order a second and identical satellite. Meanwhile, the prime contractor had changed both CAD and analysis applications a number of times over this time. During the changes of tools, the original satellite data was not retained. Thus, the data was simply lost, which required the contractor to redo ALL of its engineering work. Lifetimes of 75 years and more are common for aircraft, power plants, oil & gas production units, buildings, ships, and other products.

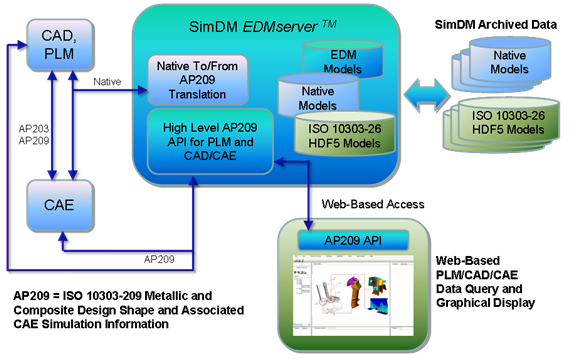

Jotne EPM’s Simulation Data Management (SimDM) program supports the management of engineering analysis data for product design by using an analysis-vendor independent implementation platform to combine CAD and engineering data into one comprehensive data set. Along with providing users better control over their data, this feature of SimDM enables long-term data archival.

CIMdata calls this area of PLM data management Enterprise Simulation Management (ESM). ESM continues to become more important as companies realize that cost, quality, and productivity can be positively impacted through the management of analysis and simulation data, similar to the benefits achieved by managing other product development information.

In the past, most analysis organizations have maintained their simulation and analysis data and processes separate from the broader enterprise’s product definition information. This has been due to a number of factors including the large data sets required, and essential differences between analysis data models and design data models. Thus, investments in simulation and analysis have typically been targeted at focused technologies used by specialists to more precisely analyze the performance of alternative product designs, with simulation and analysis treated as a specialty area that is rather disconnected from the overall product development organization. Simulation investments typically have not focused on linking simulation more effectively into the broader enterprise.

Today, employing ESM techniques can significantly improve the overall product development process. ESM helps integrate simulation activities into the enterprise to support the capture and reuse of simulation and analysis knowledge. Further, SimDM provides benefits for companies that use analysis codes from multiple sources. By allowing companies to use the solvers and analysis applications they already know and trust; SimDM preserves knowledge and expertise and improves the effectiveness of simulation and analysis programs and sharing analysis information. As product analysis and simulation continues to become capable of supporting full systems simulation, combining control systems, electronics, motion, structural analysis, and more, a managed simulation environment becomes even more critical.

Creating an analysis data repository that is readily accessible and that can be integrated with many different tools and data management solutions requires using a consistent set of data exchange standards. Jotne has adopted standards as a core component of their product suite; for instance, using the ISO 10303-239 PLCS standard in their EDMmodelServer™ product. For SimDM, they use ISO 10303-2091 combined with the HDF52-based ISO 10303-26 data persistence format to facilitate the storage of large analysis data sets. This work has been supported by the Lockheed Martin Aeronautics Company which has provided requirements for SimDM and continues to be one of the stakeholders of AP209. ISO10303-209 and ISO10303-263 are part of the family of standards known as STEP. HDF5 defines a platform-independent file format and API for storing very large datasets like those used to support simulation and analyses. It also takes care of data type conversions. HDF5 is based on open-source software.

The SimDM Data Management Architecture

The use of the ISO standards and EXPRESS Data Manager provides a high-speed database system that solves current constraints on long-term retention of analysis data, supporting cost-effective, speedy, and integrated analysis capabilities including data streaming for visualization. By being an internationally-accepted, maintained, and openly-available standard, AP209 has the characteristic of longevity, a necessity for enabling long-term data retention. The data representation is independent of the software that uses it, with the standard data model itself being the data dictionary. The data model of AP209 is very rich. Not only does it cover engineering analysis data; it also includes the CAD data and associated PLM information that is being analyzed, thus enabling the traceability of simulation results back to the original product geometry. Further, it supports AP209-based (and some limited native-based) integrations for data export and import with CAE tools such as MSC PATRAN, Altair Hypermesh, ABAQUS, and others. With this, the architecture of SimDM provides simulation data archiving.

Jotne’s products SimDM and EDMmodelServer use the same basic software including the database and the functions used to develop translators, integrations, and archival solutions including verification. The differences in the products become apparent in their business uses, user interfaces, and APIs.

SimDM brings the capabilities of the AP209 model to the analysis user. By making simulation data readily available within a common platform based on STEP, SimDM helps companies expand access to analysis information. The solution is particularly aimed at organizing very large data sets for complex analyses. The benefits of managing this data has very positive impacts on product development by supporting the creation, capture, and management of critical simulation and analysis data and results, intellectual assets that are critical to enabling innovation. In addition, SimDM makes simulation data available to all who have to use it and secures simulation and analysis data for future access, even when the CAD and CAE systems have disappeared from the market.

CIMdata believes that Jotne’s SimDM product offers companies that are developing, analyzing, simulating, and supporting complex products an effective capability to manage their ESM information both in the short- and long-term. Supporting a simulation and analysis repository built upon open international standards facilitates long-term information independence and enables a comprehensive ESM strategy. For more information about Jotne’s products, go to www.epmtech.jotne.com.

1 ISO 10303-209 ed2 is Multidisciplinary analysis and design (AP209 ed1 was known as Metallic and Composite Design Shape and Associated CAE Simulation Information)

2 HDF5 is Hierarchical Data Format Version 5, which is specifically developed to allow storage and retrieval of very large scientific data sets

3 ISO 10303-26 is Binary representation of EXPRESS-driven data, which uses HDF5 as its underlying file format