Key takeaways:

- CIMdata believes that Mevea offers a exceptional end-to-end solution approach (from inception to in-service operation)—enabling effective digital twin solutions for its customers.

- Digital Twin as a technology, even though relatively young, is developing rapidly. It is the required foundational technology to enable cognitive behavior in real life in the future.

- Mevea’s digital twin approach should allow its customers to not only achieve competitiveness, but sustainable product and process innovation.

Manufacturing OEMs and their suppliers need to remain globally competitive. Unfortunately, this is becoming a significant challenge for most companies in today’s rapidly changing, globally competitive environment. Products, processes, and the global business environment we are living in are exploding with innovation. Embedded systems combined with interactive environments are playing a major role in the ever-increasing complexity of product design, development, and on-going refinement, as well as manufacturing and service in the connected world of the Industrial Internet of Things (IIoT). To achieve and maintain the required level of competitiveness, a system modeling and simulation approach to product and process development, and continuous support and refinement must be adopted. Such a system modeling and simulation approach must also support and enhance the interactions across the entire product system, internally, as well as externally to satisfy changing demands and market trends. Some of the most important challenges and market trends facing businesses regardless of industry are:

- The global economy. Today’s markets are globally connected, interact with each other, and to a certain degree, depend on each other. Companies with a global presence are challenged with a huge variety of regional and local legislation that needs to be considered when designing, manufacturing, and selling their products and services, as well as when they interact with their consumers. Consumers interact and react to new products and technologies differently across the various regions of the world. This adds several additional variables to the equation when bringing products to market.

- Digital Threads, Digital Twins, and Industrial Internet of Things. These require the availability and use of real world product performance data and related simulation models through the entire product lifecycle. Companies with well-organized data management systems and infrastructure in place to access this data and bring it together rapidly in a meaningful way will have a clear market advantage.

- Drastically reduced time to market demands. A given for almost all industries and products. Markets are changing very rapidly, customers are demanding delivery now and not having to wait for tomorrow, and there is little to no tolerance for product delays.

- Model-based enterprise enablement. For success in today’s rapidly evolving markets, creating the infrastructure to support a model-based enterprise is essential. A model-based enterprise can reduce time-to-market and overhead costs by enabling companies to virtually predict product behavior and performance before a single product is delivered to the market. Also, virtual modeling can help improve product quality and overall product robustness.

- Demand for more flexibility and choices. The movement towards the age of experience and personalized mass customized products and related experiences is upon us—customers want what they want, how they want it.

- Real-time and virtual access to product related data. Companies need the ability to rapidly access as much relevant product data as possible to make informed decisions and share their experiences in real-time.

- Sustainability. Companies must focus on how their products interact with nature and how they make effective use of natural resources. A similar and even more important role is the sustainability of the business itself and within the community as an entity.

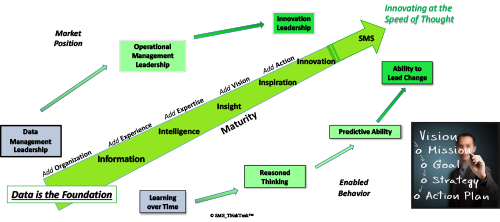

In many cases, innovation is the key differentiator. Open and extensible systems engineering environments to support development with integrated modeling and simulation tools that enable process and data management, as well as support decision-making and collaboration are necessary. Such an approach needs to leverage a common system engineering and product data model (i.e., model-centric systems engineering) that encompasses well written requirements, platform, program, project, system definition, product structure, lifecycle, and configuration-management capabilities. At the same time, information and data need to be ready and accessible, more or less in real-time, especially in the context of IIoT. Such thinking goes beyond traditional systems engineering thinking and is highly iterative at all stages and levels of the lifecycle. The various levels to be enabled by such an approach are shown in Figure 1.

Figure 1—Innovating at the “Speed of Thought”

(Courtesy of SMS_ThinkTank™)

An upcoming technology supports the utilization of the “so-called” Digital Twin. Essentially, a digital twin is a virtual representation of the real-world product and the environment in which it operates (i.e., its elements and dynamics). It integrates models (e.g., CAD and simulation models), artificial intelligence, machine learning, and software analytics with operational data to create living digital simulation models that update and change as their physical counterparts in the real-world change. Such digital representations can be used in several ways, including:

- Project the real-world status of an object onto the virtual model to help optimize its performance in real-time.

- Optimize the operation and maintenance of physical assets, systems, and manufacturing processes.

- Develop and optimize products before they are deployed for the specific use and operating environment for which they are targeted.

The first mentioned use case is the ultimate application for the digital twin, where together with predictive analytics and real-time connectivity, cognitive behavior can be enabled. The second use case is, in popular and current technology phases, “readily available to the end user,” at best in “near to real-time” and often used for offline optimization, while the third use case sets the stage before a physical asset is deployed and placed into operation. Still, the third use case is the first stage for creating the digital twin. The enabling simulation technology required is very much the same as for the other two use cases. The only thing at this stage that is not necessarily required is the IIoT engine.

Nowadays, simulation solution providers are way too often focused on achieving higher fidelity modeling (i.e., the use of multi-physics and multi-domain approaches and technologies). Fortunately, many are starting to connect to the lower fidelity world (e.g., utilizing 0D/1D modeling techniques), but it is just the beginning. A comprehensive system approach that connects fully to the real world (one that does not stop with the completion of the virtual model) is lacking.

Multibody dynamics simulation (MBD), initially focusing on bringing the rigid bodies of a system together, seemed to be the answer for lower fidelity approaches to connect virtual models and real-world physical asset. It has become evident that even in the 0D/1D world a more accurate solution is needed. Thus, enabling flexible bodies as part of MBD simulations has also become important. Furthermore, MBD plays (or needs to play) a central role in modern systems engineering approaches utilizing model-based systems engineering (MBSE). Thus, the focus is now being placed on multibody systems dynamic simulation (MBS).

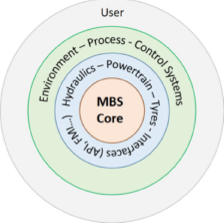

At the core, Mevea offers a modern MBS solution and has combined its MBS with its simulator offerings. This distinctive combination provides Mevea’s customers the opportunity for gaining extensive knowledge from a systems engineering perspective, as well as an enhanced ability focus on bringing the virtual and physical worlds closer together in a single model that allows real-time interaction. The digital twin concept within the Mevea solution started to take shape with the realization from the very beginning that it has to be flexible in terms of being able to connect to various solutions to provide an open and flexible structure (see Figure 2).

Figure 2—Mevea's MBS Core built for real time Simulation

(Courtesy of Mevea)

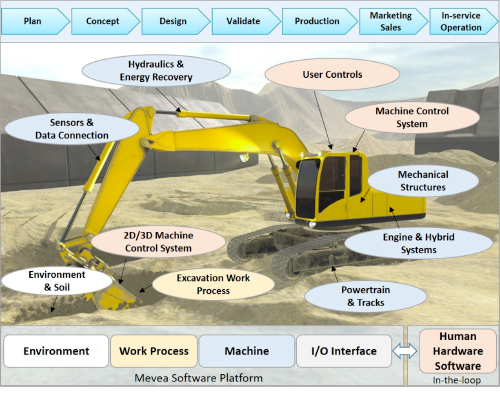

Mevea has developed a rather exceptional end-to-end solution approach bringing the real world into the digital world, by spanning the entire lifecycle enabling the simulation of the various physical effects from multi-body simulation over hardware-in-the-loop (HiL) and software-in-the-loop (SiL) to human-in-the-loop (HuiL). With its real-time simulation capabilities, it has the basics to interact directly between the digital model and a real-world asset. In addition to this, the operating environment can be brought easily into the virtual model, like for instance, the utilization of drones to capture the terrain of a quarry or construction area (i.e., through the use of photogrammetry). This allows a company to accurately plan and predict behavior of a physical asset before it is placed into its real operating environment. It also provides the operator the ability to practice and test in the virtual environment while “interacting” with the real world (see Figure 3).

Figure 3—Mevea’s End-to-End Solution Approach for Digital Twin

(Courtesy of Mevea)

The next step is to continuously monitor the asset during operation and compare its actual performance with the digital twin established during development. This way, it moves onto the next stage in its lifecycle while maintaining the digital thread. This capability can provide Mevea’s users with the ability to react to changes quickly and precisely, thus increasing their competitiveness (see Figure 3).

CIMdata believes that digital twin technology is just at the very beginning of finding its way into actual applications. Many solution providers are still developing appropriate offerings to effectively enable the ultimate digital twin use cases. CIMdata believes that Mevea’s end-to-end digital twin solution approach is matchless and very promising. For its customers, it should play a central role in achieving not only competitiveness, but sustainable product and process innovation.