Key takeaways:

- Siemens PLM Software and Bentley Systems team to deliver a closed-loop digital solution to resolve factory floor issues.

- Siemens IoT system, MindSphere, and Bentley Systems’ AssetWise solutions monitor intelligent devices and assets to identify production issues and trigger corrective actions.

- Siemens NX with Convergent Modeling and Bentley Systems’ ContextCapture support a union of mesh and precise geometry product modeling to define real world assets.

Product engineers have long understood that CAD product models represent physical products in a virtual world. They author the shape and function of the virtual models, simulate and analyze their performance in a virtual environment, and plan and replicate the manufacturing processes of those products in a virtual factory. This virtual/real concept has now advanced into a more encompassing concept of the digital twin. Siemens defines digital twin as a cross-domain digital model that accurately represents a product, production process, or performance of a product or production system in operation. The digital twin of a product evolves and continuously updates to mirror any change to its physical counterpart throughout the product’s lifecycle. Now, Siemens has teamed with Bentley Systems to deliver a solution that allows product engineers to complete the loop from design through to operation and monitoring performance on the factory floor. If an issue is identified, the product and its digital twin can be updated, with updated parts produced and installed. CIMdata applauds Siemens and Bentley for demonstrating the effectiveness of the digital twin and encourages them to continue the evolution of the concept to provide improved manufacturing, better quality, and cost performance for their users.

Walking the Loop from Production Error to Solution

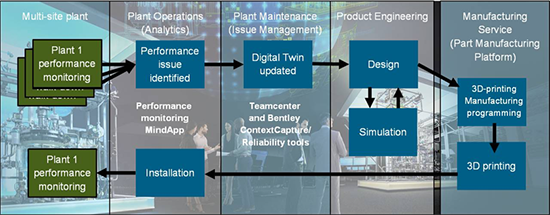

Machine failures and performance slowdowns are common occurrences on the factory floor. The joint demonstration walks the observer through the closed loop of identification of systems that will lead to a machine failure, logging the issue in the digital twin, modifying the machine design, and analyzing its performance, followed by 3D printing the newly designed modules and installing them so that performance monitoring can be resumed.

In essence, the software solution is not just capable of monitoring a problem, but with a feedback loop into PLM, the problem can be fixed. The demonstration shows how in a smart factory a problem or future problem is first identified by capturing real-time diagnostic information, and then taking actions based on insight gained from the performance of the digital twin. The combined Siemens and Bentley software solution can optimize product and plant performance based on insights by leveraging the digital twin.

The flow of the demonstration is captured in Figure 1.

Figure 1—Digital Twin Demonstration Flow

(Courtesy of Siemens PLM Software)

CIMdata commends the two companies for building a real life scenario of an entire value chain rather than a string of disjoint examples of their products’ functional capabilities. The walkthrough lends credence to the full suite of solutions the companies can leverage to solve real problems in the design and manufacturing world.

The demonstration is staged using the Siemens’ MindSphere environment as a backdrop. MindSphere is the cloud-based Internet of Things (IoT) operating system from Siemens that lets users connect their machines and physical infrastructure to the digital world. "Fleet Manager for Machine Tools" is a new Siemens app for MindSphere that facilitates the monitoring of machine tools worldwide whether at small or large production sites. Using these solutions a manufacturing company can observe large volumes of data from intelligent devices on the factory floor. Bentley Systems provides the ability to analyze and control relevant asset information using their AssetWise suite of tools for decision support. In effect, users can automate the exploration of asset performance data to trigger actionable resolution of problems on the factory floor.

The demonstration continues with a supposition that a manufacturing machine has failed (or is in danger of failing soon) and that not all its component pieces were modeled in NX, Siemens flagship CAD solution. Bentley Systems’ ContextCapture solution, from their reality modeling software, can generate 3D mesh models from simple photographs of the target object. That mesh of planar triangles can then be imported into NX and married with precise geometry using Siemens new Convergent Modeling capabilities. A design improvement can then be modeled and analyzed with Siemens Simcenter suite of CAE solutions. Finally, the demonstration moves into manufacturing of the revised machine parts with 3D printing—the overall design and production process being managed by the Teamcenter platform.

CIMdata appreciates the completeness of the demonstration where at each step in the issue discovery and follow on redesign and manufacturing corrective process, a Siemens or Bentley Systems software solution falls precisely into place. Product developers will benefit from the expertise of the Siemens and Bentley Systems solution partnership and their eyes will be opened to the future of orchestrating product monitoring, design, and manufacturing.